Variable Frequency Drives (often known by their initials: VFDs) convert a fixed-frequency supply voltage (60 Hz in North America) to a continuously variable frequency. By controlling the frequency of the voltage supplied to an AC motor, we can control its rotational speed and minimize stress. A VFD can control two main elements of a 3-phase induction motor: its speed and torque.

Choosing the correct blower is a fundamental step in designing a functional and efficient system. We’ve covered the basics of Regenerative versus Centrifugal Blowers and Understanding Blowers as part of System, in this article we’ll show how to read a blower curve and use that information to specify the best blower for your project.

Most blower suppliers use similar types of specifications to describe the blower function. Below is an example of a typical blower spec sheet.

Air knives are used in many industries to remove unwanted materials from processes. This can range from blowing water off of bottles in a bottling facility to removing cooling fluid in a metal rolling plant to removing crumbs from a bakery conveyor system. While the use of air knives for blow-off is widespread, so are the errors in setup that cause ineffective or inefficient operation. In this article we will review some of the fundamentals of implementing an effective blow-off system.

Flow, Velocity, and Pressure Defined

One issue that seems to cause universal confusion when designing a blower-based system is understanding the differences between flow, velocity, and pressure and knowing when each metric is important. This article investigates this topic with a focus on how they relate to each other in applications with industrial blowers.

First, let’s define each term:

Achieving a perfect shrink on a sleeve label is often easier said than done. Even with a custom built system some experimentation may be necessary as you dial in the settings needed to achieve that all-important perfect shrink on your bottle, can or other packaging. Two of the primary variables to adjust are Temperature and Time; it is important to ensure they are in balance in order to achieve an acceptable final product ready for display and sale.

Temperature

One of the advantages of air heated shrink tunnels is their wide temperature range. This offers another variable that can be altered to compensate for increasing line speeds, beyond simply extending the length of the shrink tunnel. The operating temperature of the shrink tunnel may need to be increased if labels are exiting wrinkled or with uneven shrinking. Or the temperature may need to be decreased if labels are tearing or over-shrinking.

A common misconception we encounter while working with customers to develop process heat systems is that the airflow transitioning from a small space to a larger one will expand to fill any volume. While this is true (to a point) for compressed air, which undergoes a rapid volume expansion as it transitions from a high pressure environment (80-100PSI) to an atmospheric environment, it is not true for blower-based systems where this pressure change does not exist.

Airflow from a blower-based system will always follow the path of least resistance; this means air will continue to travel straight away from an outlet unless forced to change course. There may be some spreading effect from the moving air traveling through still air and some rise if the air is hot; however, for practical purposes this effect is negligible. When designing a blower-based system, one must make specific design choices to equalize flow and avoid uneven heating patterns. Here are a few problematic examples we see again and again:

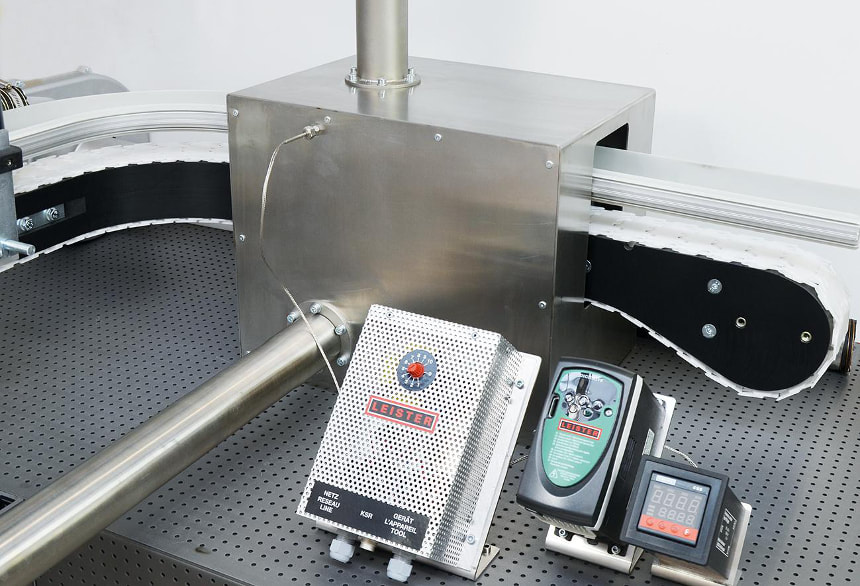

In order for the air to diffuse as needed, it must be influenced and directed. This is most commonly done by strategically: restricting the outlet, installing deflectors and baffles within the system, or combining both of these solutions. Inside every Leister hot air tool is a heating element composed of a ceramic honeycomb supported resistance wire filament (See below). Electric resistance wire heaters work on the principle that when electrical current passes through a conductor heat is generated, and the amount of heat generated is related to the resistance of the conductor.  Figure 1: Leister Heating Element Figure 1: Leister Heating Element Some resistance wire heaters are able to function without airflow because they have been designed in such a way that they will not reach temperatures above their safe operating limits. Examples include: a toaster, some ovens, wrap heaters, some space heaters, etc. However, Leister heaters are designed to operate at very high temperatures—most are designed to heat airflows up to 650°C, and some up to 900°C—and as a result require airflow at all times. To reach these high air temperatures, the heating element must be capable of reaching even higher temperatures. Without adequate airflow, the element will heat up unchecked and will exceed safe limits, leading to the destruction of the element.

Although blowers are commonly used in manufacturing, it can be difficult to find good sources of information on the different types of blowers and how to choose the appropriate one. The purpose of this article series is to give a good, basic understanding of the different types of blowers and provide you with the technical information required to make a good decision for your application.

Recommended Reading Blower Selection Examples

In order to make the information in the previous articles more tangible let’s look at a number of scenarios and the thought process that might go into selecting a blower for each one.

Although blowers are commonly used in manufacturing, it can be difficult to find good sources of information on the different types of blowers and how to choose the appropriate one. The purpose of this article series is to give a good, basic understanding of the different types of blowers and provide you with the technical information required to make a good decision for your application.

Recommended Reading Blower Choice: What are the important design parameters?1. Understand your Requirements

The first step in blower selection is to understand the application requirements. Below are some of the questions you should ask yourself:

These types of questions should narrow the focus to one or two types of blowers. As with any engineering problem, there is not always a single solution and there can be some overlap in the characteristics of two different blowers. For a refresher on the most common types of blowers available, see Part 1: Impeller-based Blowers and Part 2: Positive Displacement Blowers. Why you Can’t Measure Air Temperature with a Laser IR Gun and a Simple, Effective Alternative7/18/2018

While Laser IR Thermometers are an extremely common tool, they are entirely ineffective for measuring the outlet temperature of an air heater. To understand why, we must first understand how this tool works. Laser IR Thermometers measure the surface temperature of an object by measuring the thermal energy emitted by the target. Knowing the amount of thermal energy discharged and the emissivity of an object’s surface, the object's temperature can be determined by the device.

When measuring a heater’s output air temperature, the largest issue with these tools is that they measure surface temperatures. As the heated air is transparent, the measurement will always be the surface temperature of a nozzle or a component of the heater housing; and frequently it will be an exterior surface. These items will always be cooler than the heated air, often by a significantly larger margin than the user would expect. To accurately measure the output temperature of an air heater you must measure air temperature and laser IR thermometers are incapable of doing so. |

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: