|

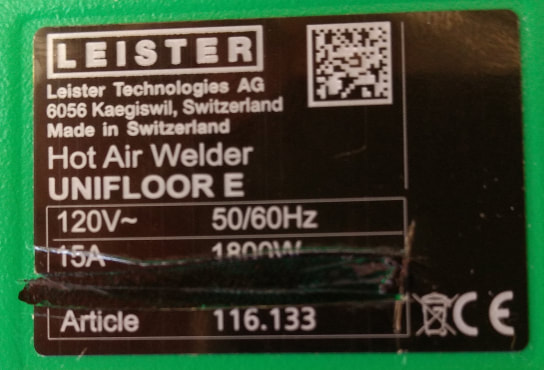

Keep an eye out when buying used (and even new!) equipment to make sure the nameplate is intact and hasn’t been altered in any way. We’ve helped a few customers deal with serial numbers cut or scratched out of nameplates. The serial number is the easiest way to confirm age and ownership of a Leister tool. Without a serial number, the manufacturer’s warranty is unusable. You could even be purchasing a stolen piece of equipment. Don’t get caught! Check before you buy.

The serial number has been cut out of the nameplate on this tool and a poor attempt has been made to cover the resulting gap with black marker. This tool was purchased brand new from an unauthorized distributor. The equipment was not electrically certified for use in Canada and had not been modified to be compliant with the Canadian Electrical Code. The tool carries no warranty as a result.

Learn our top 5 tips for properly caring for your hot air welding tools and minimizing maintenance.

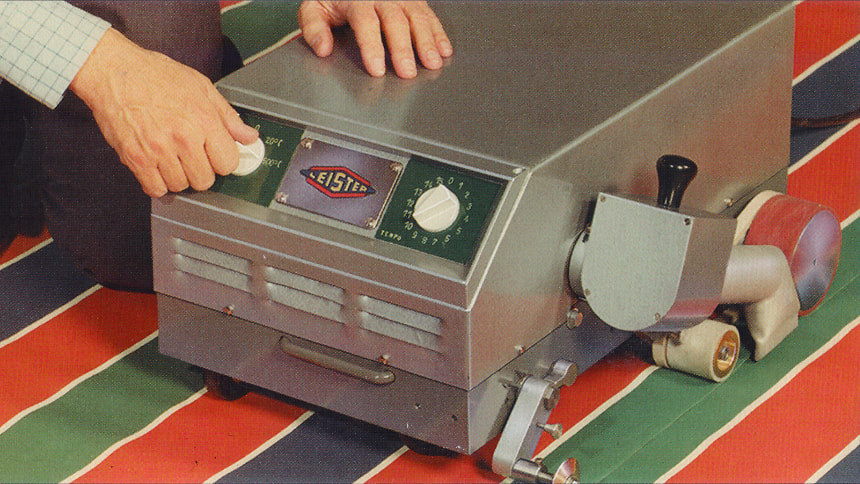

The Leister UNIFLOOR is a fast, reliable welding machine for installing linoleum, rubber, PVC, or TPU flooring surfaces. This quick how-to guide will get you started welding flooring in no time!

Inside every Leister hot air tool is a heating element composed of a ceramic honeycomb supported resistance wire filament (See below). Electric resistance wire heaters work on the principle that when electrical current passes through a conductor heat is generated, and the amount of heat generated is related to the resistance of the conductor.  Figure 1: Leister Heating Element Figure 1: Leister Heating Element Some resistance wire heaters are able to function without airflow because they have been designed in such a way that they will not reach temperatures above their safe operating limits. Examples include: a toaster, some ovens, wrap heaters, some space heaters, etc. However, Leister heaters are designed to operate at very high temperatures—most are designed to heat airflows up to 650°C, and some up to 900°C—and as a result require airflow at all times. To reach these high air temperatures, the heating element must be capable of reaching even higher temperatures. Without adequate airflow, the element will heat up unchecked and will exceed safe limits, leading to the destruction of the element. Why you Can’t Measure Air Temperature with a Laser IR Gun and a Simple, Effective Alternative7/18/2018

While Laser IR Thermometers are an extremely common tool, they are entirely ineffective for measuring the outlet temperature of an air heater. To understand why, we must first understand how this tool works. Laser IR Thermometers measure the surface temperature of an object by measuring the thermal energy emitted by the target. Knowing the amount of thermal energy discharged and the emissivity of an object’s surface, the object's temperature can be determined by the device.

When measuring a heater’s output air temperature, the largest issue with these tools is that they measure surface temperatures. As the heated air is transparent, the measurement will always be the surface temperature of a nozzle or a component of the heater housing; and frequently it will be an exterior surface. These items will always be cooler than the heated air, often by a significantly larger margin than the user would expect. To accurately measure the output temperature of an air heater you must measure air temperature and laser IR thermometers are incapable of doing so.

A welding rod, as recommended by the manufacturer, must be used when installing linoleum, rubber, PVC, or TPU surfaces. Welding rods are generally available with 3 to 5 mm diameters. Speak with your material manufacturer or supplier to find out more.

Before welding, the seam edges must be milled or grooved to approx. 2/3 of the thickness of the material. The welding rod is then welded into the groove to create a strong bond. It is important that the welding rod fully penetrates the milled groove otherwise the seam may fail prematurely. The welding rod is then trimmed in two stages: The first pass is done with a trimming guide immediately after welding. This removes the bulk of the excess rod. The second pass is done once the material has cooled completely. This helps prevents concave seams, producing an even, flush seam with a long service life. Electrical Certification for use in Canada: Recognizing Certification and Why it’s Important9/23/2014

Electrical certification is a must for any electrical tools bought, sold, or used in Canada. Tools must be tested by an accredited certification organization to determine that they meet the applicable safety standards and adhere to the Canadian Electrical Code. The Standards Council of Canada handles the accreditation of inspection bodies and together with provincial Safety Authorities oversees enforcement.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: