|

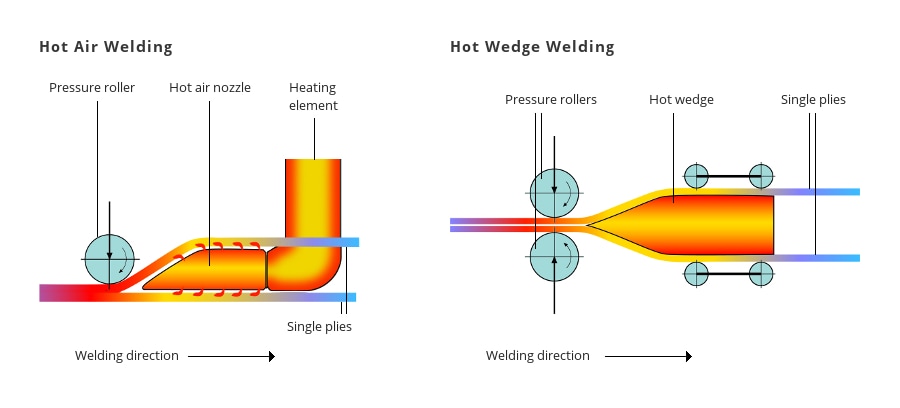

The main difference between a wedge and a hot air welder is the way in which heat is transferred to the material. With a wedge welder, a solid piece of metal—the wedge—is heated and inserted between the two pieces of material. With a hot air welder, air is heated and then delivered between the two pieces of material via a hot air nozzle.

Why is using the correct tool for the job important? Results.

Using a tool that is undersize for the job will give you unsatisfactory welding results. There are two factors at play: power and weight.

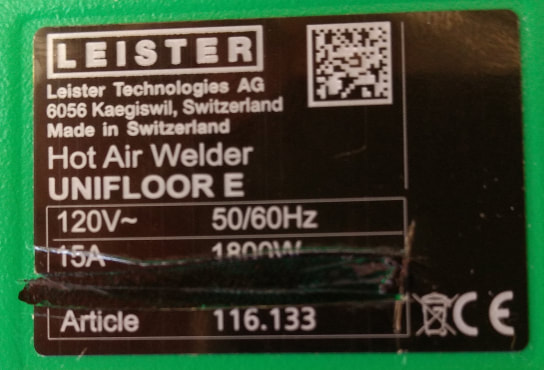

Keep an eye out when buying used (and even new!) equipment to make sure the nameplate is intact and hasn’t been altered in any way. We’ve helped a few customers deal with serial numbers cut or scratched out of nameplates. The serial number is the easiest way to confirm age and ownership of a Leister tool. Without a serial number, the manufacturer’s warranty is unusable. You could even be purchasing a stolen piece of equipment. Don’t get caught! Check before you buy.

The serial number has been cut out of the nameplate on this tool and a poor attempt has been made to cover the resulting gap with black marker. This tool was purchased brand new from an unauthorized distributor. The equipment was not electrically certified for use in Canada and had not been modified to be compliant with the Canadian Electrical Code. The tool carries no warranty as a result.

Test welds are an important part of welding thermoplastics whether they’re used for roofing, tarps, pools, tunnels, landfills, or tailings ponds. Welds should be tested first thing in the morning and several times throughout the day to ensure that environmental changes are not compromising the strength of your welds.

Learn our top 5 tips for properly caring for your hot air welding tools and minimizing maintenance.

Patching is a quick and economical way to prolong the life of tents, tarps, and other items made from industrial fabrics.

Welding fabrics by hand is an easy and inexpensive way to complete small jobs, build prototypes, or complete repairs either in the shop or the field.

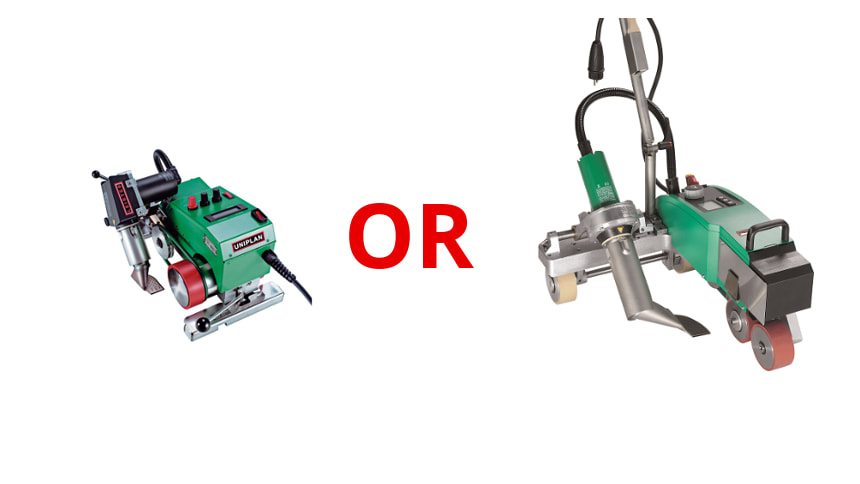

You’ve read our article on Industrial Fabrics Joining Methods and selected hot air welding (which carries several advantages), now it’s time to pick which machine is best for the job. Broadly, there are two types of hot air welding tools: automatic and manual. Automatic tools can be further broken down into moving and stationary.

There are several different joining methods for industrial fabrics including gluing, sewing, chemical welding, and heat welding. The type of project, where it will be used, and the desired lifespan of the final product all affect the choice of method.

Inside every Leister hot air tool is a heating element composed of a ceramic honeycomb supported resistance wire filament (See below). Electric resistance wire heaters work on the principle that when electrical current passes through a conductor heat is generated, and the amount of heat generated is related to the resistance of the conductor.  Figure 1: Leister Heating Element Figure 1: Leister Heating Element Some resistance wire heaters are able to function without airflow because they have been designed in such a way that they will not reach temperatures above their safe operating limits. Examples include: a toaster, some ovens, wrap heaters, some space heaters, etc. However, Leister heaters are designed to operate at very high temperatures—most are designed to heat airflows up to 650°C, and some up to 900°C—and as a result require airflow at all times. To reach these high air temperatures, the heating element must be capable of reaching even higher temperatures. Without adequate airflow, the element will heat up unchecked and will exceed safe limits, leading to the destruction of the element. |

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: