|

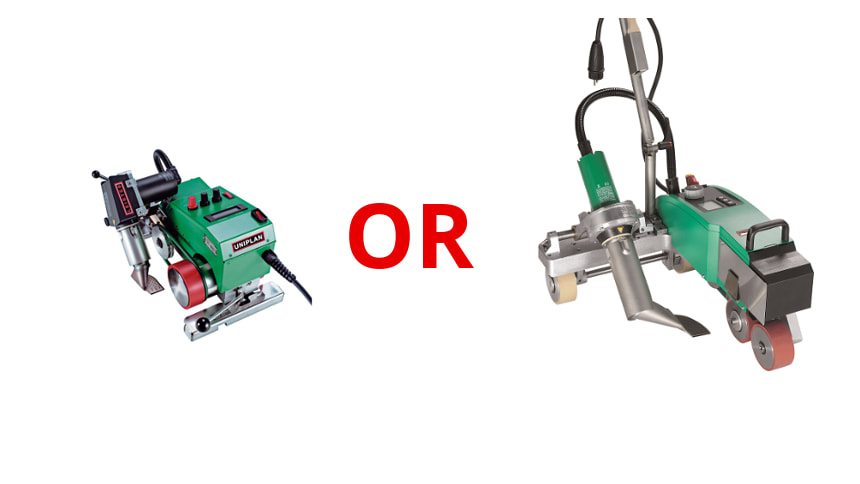

Why is using the correct tool for the job important? Results.

Using a tool that is undersize for the job will give you unsatisfactory welding results. There are two factors at play: power and weight.

An underpowered tool will have trouble heating the material sufficiently to achieve a good weld. Sometimes a lack of power can be compensated for by decreasing the speed of the machine but often the result is still an incomplete weld.

The thicker the fabric the more weight is required to ensure a good weld. Although supplementary weights can be added to machines, adding weight beyond what is recommended by the manufacturer will cause the machine to work harder and break down more often. Another consideration when selecting the correct tool is speed. If your application requires long, straight welds a machine that is capable of greater speeds is an asset. However, if you are welding short lengths, speed may be less important allowing you to purchase a less expensive machine or if you are welding curved seams a slower machine that allows you to fine-tune as you weld may be more suitable. Customers often ask us if they can use a smaller, less-expensive tool as an alternative to the machines designed for their industry. The answer is typically: not with good results. For help selecting the correct tool for your material contact your Technical Sales Representative. Originally published 02/18/2016 Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: