|

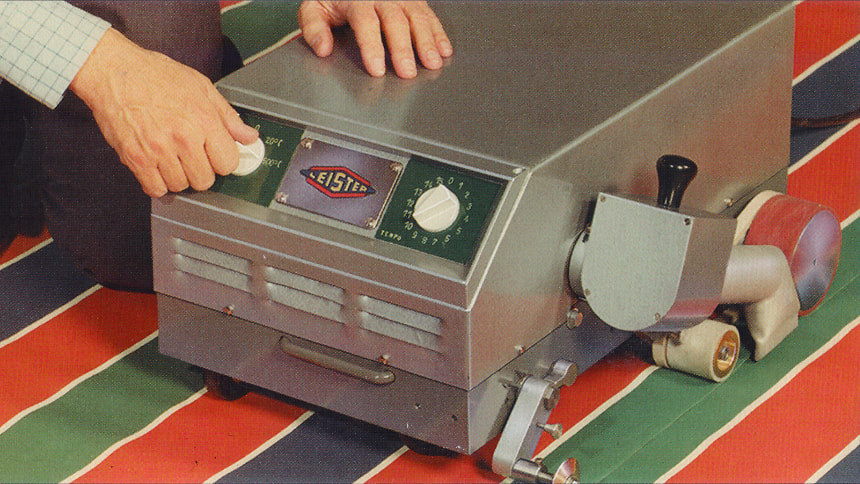

Learn our top 5 tips for properly caring for your hot air welding tools and minimizing maintenance.

1. Cool it down before shutting it off

Run tools with the heat turned off for 5-10 minutes or use the built-in automatic cool-down mode if available to cool down tools before shutting them off. Shutting off a hot tool causes thermal shock to the element which leads to premature failure. 2. Move and lift properly Don’t lift hand tools by their cords. Correct automatic tools using their handle, not by pulling on the cord. Lift automatic tools with the integrated handles and chassis, not by grasping the blower. 3. Clean thoroughly after use Clean nozzles with a wire brush while hot to remove debris. A blocked nozzle can impede air flow through the tool, potentially causing it to overheat. Clean excess extrudate from welding shoes by inserting a piece of welding rod into the end, waiting several seconds, and then pulling. If extrusion welding with PVC, be sure to flush the extrusion screw with PE rod at the end of each day to prevent corrosion. 4. Clean the air intake regularly Clean the air intake on tools regularly with a soft brush or compressed air. A restricted air intake can cause a tool to overheat causing damage. Ensure the tools air intake is not placed on a bench with small particulates that may be pulled into the tool. 5. Regular maintenance Most tools need small regular maintenance such as changing brushes or elements, or replacing tires as these parts wear out or become damaged. Simple maintenance can be handled yourself but only if you catch it before it becomes a bigger problem. Check out our Tech Tip’s section for common problems and repairs you can do yourself. If you tool develops larger problems send it in to our Authorized Leister Repair Centre in Burlington ON. Originally published: 01/28/2015 Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: