|

Both regenerative and centrifugal blowers are widely used in industrial processes. Superficially the two types of blowers can seem similar and it can be difficult to find good information on the differences between the two types of blowers and why one would be selected over the other.

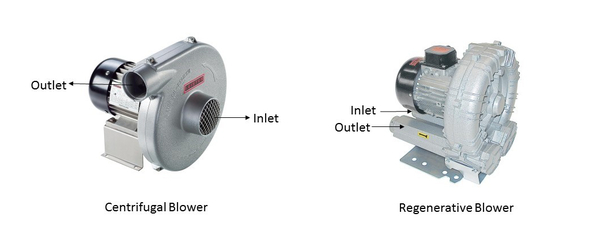

First, we’ll discuss what the two types of blowers have in common. Both types move air using an impeller on a rotating shaft. The air comes in the inlet and is focused while traveling with the impeller before exhausted as linear flow at the outlet. This is where the similarities end. How can you tell the difference?

The difference in construction between a centrifugal and regenerative blower make it easy to tell the two apart by sight. A centrifugal blower is configured so that the inlet and outlet are perpendicular, with the inlet feeding air into the centre of the impeller and the outlet tangential to the rotation of the impeller. In a regenerative blower the inlet and outlet are parallel with both positioned perpendicular to the rotation of the impeller

What is the practical difference?

The impeller and impeller casing of the two types of blowers are designed for different end uses. In centrifugal blowers, air enters at the center of a rotating impeller on which there are a number of fixed vanes. As the name implies, centrifugal blowers move air through centrifugal action, air is forced to the periphery of the impeller and housing where it is discharged as a steady stream through the outlet. The negative pressure created at the centre hub, in turn, sucks in more air. The vanes basically act as paddles to push volumes of air to the outlet. No significant pressure is built up in this process but centrifugal blowers can be used to move large volumes of air.

In regenerative blowers, as the impeller pushes the air around the ring, centrifugal forces cause the air trapped between the rotating impeller vanes to move towards the blower casing. The air flow is then forced to the base of a following impeller vane for recirculation in the same manner. This circular flow in combination with the revolution of the impeller causes air to follow a spiral path through a regenerative blower (see picture); the result is air that is under constant acceleration. This "regeneration" of air with each revolution allow regenerative blowers to develop significant pressure. As a general rule centrifugal blowers are considered low pressure, high flow blowers while regenerative blowers are high pressure, low flow blowers. These fundamental characteristics inform the types of applications to which they are suited. Where to use what?

Centrifugal blowers work for applications such as heating a furnace with hot air where a large air volume is required to fill the space. Blow-off applications are generally better suited to centrifugal blowers because large volumes of air are required to get optimum air velocity out of air knives.

Regenerative blowers can produce enough pressure to overcome air flow constraints in a process system; for example, if a nozzle is required that constricts the air flow from a large cross section to a smaller cross section. If the air is required to travel a suboptimal path with sharp bends or a torturous route the pressure of a regenerative blower will be useful. For more information on blowers see our whitepaper on blowers. If you would like to speak with someone about your specific application please contact STANMECH Technologies and we would be happy to help. Originally Published: 02/20/2015 Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: