|

Although blowers are commonly used in manufacturing, it can be difficult to find good sources of information on the different types of blowers and how to choose the appropriate one. The purpose of this article series is to give a good, basic understanding of the different types of blowers and provide you with the technical information required to make a good decision for your application.

Recommended Reading What are the different types of blowers?

At its most basic level a blower is a tool that draws in air at an inlet and pushes air out as a steady stream at the outlet. Blowers can largely be classified into two categories: impeller based and positive displacement. Impeller based blowers have fins that radiate outwards from a rotating central axis. Positive displacement blowers use a mechanism of filling and emptying chambers at the inlet and outlet, respectively, to create flow. The fundamental difference between the two is that impeller based blowers have output flow that varies with pressure whereas positive displacement blowers have a more constant output flow regardless of change in pressure.

2. Positive Displacement Blowers

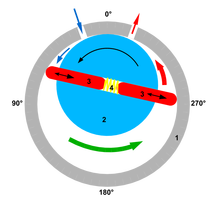

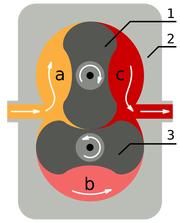

Positive displacement blowers create flow by filling and emptying chambers of air; these blowers produce flow which is relatively independent of operating pressure. There are several variations available which use the same premise but slightly different design. Here we discuss two popular types: rotary vane and rotary lobe.

Rotary Vane

Rotary Lobe (Roots Blower)

Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: