Variable Frequency Drives (often known by their initials: VFDs) convert a fixed-frequency supply voltage (60 Hz in North America) to a continuously variable frequency. By controlling the frequency of the voltage supplied to an AC motor, we can control its rotational speed and minimize stress. A VFD can control two main elements of a 3-phase induction motor: its speed and torque.

Motor-driven systems are typically designed to operate at peak load. This leads to energy inefficiencies when a system is running at a reduced load over time. A variable frequency drive gives an operator the ability to adjust the speed of the motor, matching the motor output and load requirements, thus resulting in energy savings.

VFDs are used for two main reasons:

Why use a VFD with your blower motor?

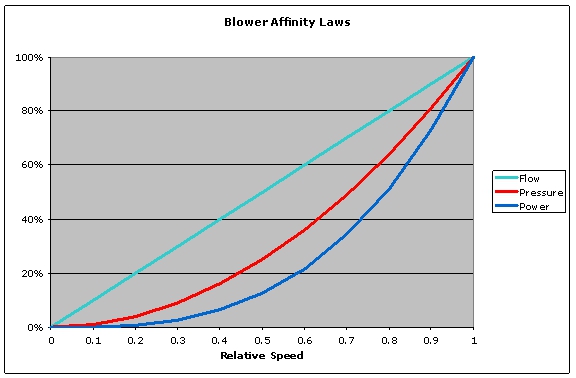

The rate of rotation for an industrial blower’s blades is driven by its motor speed; even a small reduction in speed can result in significant energy savings.

The blower affinity laws govern the relationship between rotation speed, flow, and power. The laws state that:

Therefore, in a practical application where speed has been reduced to 75 percent of the design speed:

Besides saving energy, VFDs are also used to:

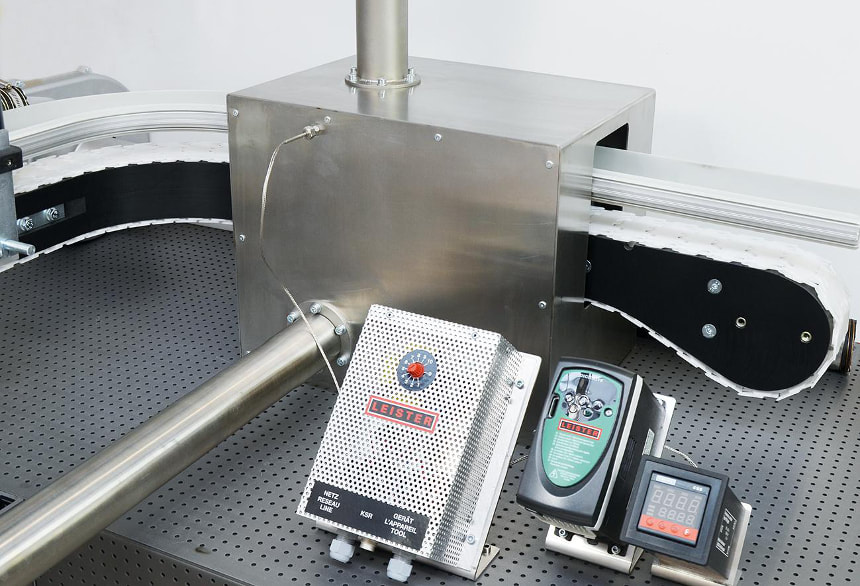

Our systems are available with Variable Frequency Drives to help reduce operating costs and ensure your system is sized perfectly to your production needs. Contact us today to find out how we can help solve your application problem. Originally published: 1/20/2014 Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: