|

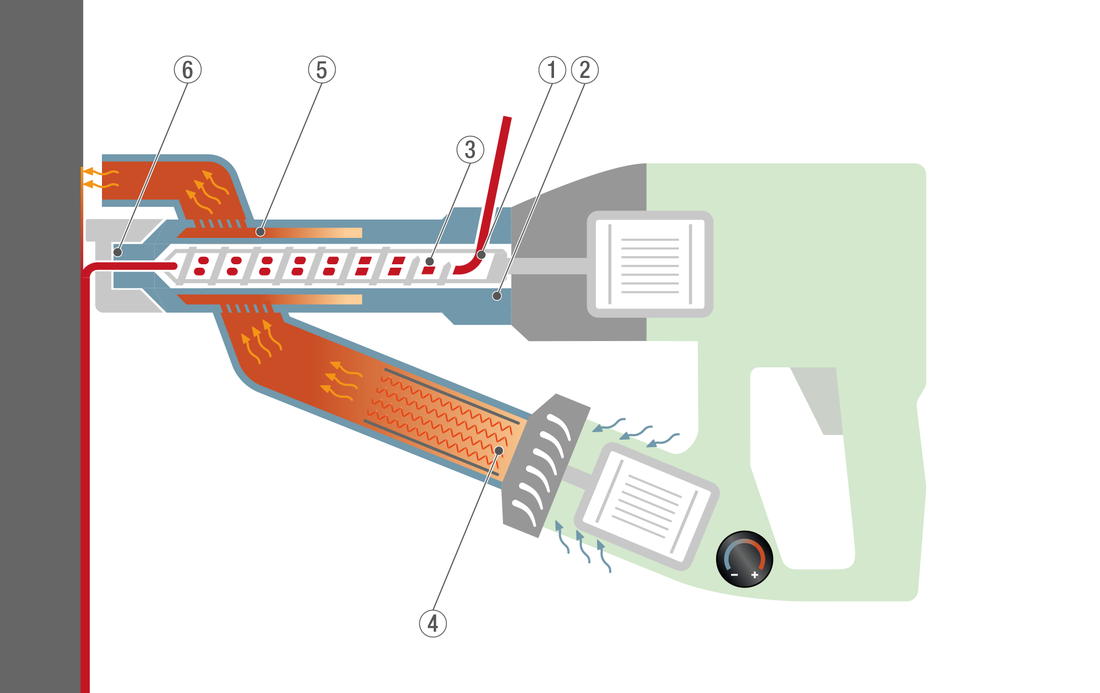

Inside every Leister hot air tool is a heating element composed of a ceramic honeycomb supported resistance wire filament (See below). Electric resistance wire heaters work on the principle that when electrical current passes through a conductor heat is generated, and the amount of heat generated is related to the resistance of the conductor.  Figure 1: Leister Heating Element Figure 1: Leister Heating Element Some resistance wire heaters are able to function without airflow because they have been designed in such a way that they will not reach temperatures above their safe operating limits. Examples include: a toaster, some ovens, wrap heaters, some space heaters, etc. However, Leister heaters are designed to operate at very high temperatures—most are designed to heat airflows up to 650°C, and some up to 900°C—and as a result require airflow at all times. To reach these high air temperatures, the heating element must be capable of reaching even higher temperatures. Without adequate airflow, the element will heat up unchecked and will exceed safe limits, leading to the destruction of the element. When PVC is melted or burned, it emits hydrogen chloride (HCl) fumes. At room temperature HCl is a colorless gas, although it will form white fumes of hydrochloric acid upon contact with atmospheric water vapor. When welding PVC the work area should be well ventilated, either naturally or through a forced air system.

PVC should only be used with an extrusion welder that specifies compatibility with the material. Components that will be exposed to PVC plastic or HCl fumes in these extruders should either be made with different materials or have a corrosion resistant coating. Using PVC with any extrusion welder without specified compatibility will result in signification corrosion to the internal components in contact with the plastic and fumes (see photos below). In the photos, the corrosion damage to the extruder screw is evident. This costly repair was completed in the STANMECH Service Centre and required the replacement of the extruder screw, extruder tube, and extruder nozzle. The damage could have been avoided by using a tool designed for use with PVC. Why you Can’t Measure Air Temperature with a Laser IR Gun and a Simple, Effective Alternative7/18/2018

While Laser IR Thermometers are an extremely common tool, they are entirely ineffective for measuring the outlet temperature of an air heater. To understand why, we must first understand how this tool works. Laser IR Thermometers measure the surface temperature of an object by measuring the thermal energy emitted by the target. Knowing the amount of thermal energy discharged and the emissivity of an object’s surface, the object's temperature can be determined by the device.

When measuring a heater’s output air temperature, the largest issue with these tools is that they measure surface temperatures. As the heated air is transparent, the measurement will always be the surface temperature of a nozzle or a component of the heater housing; and frequently it will be an exterior surface. These items will always be cooler than the heated air, often by a significantly larger margin than the user would expect. To accurately measure the output temperature of an air heater you must measure air temperature and laser IR thermometers are incapable of doing so. Repairing plastic boxes or containers is an issue in many industries. Repairing rather than replacing helps save money and is better for the environment. In this video we show you how easy it can be to repair a container if you follow the appropriate steps. Based on DVS 2207-4

1) Measured with an insert thermometer at the exrudate outlet of the hand extruder.

2) Measured 5mm in the nozzle, in the centre of the nozzle opening. 3) Drawn-in cold air volume at the ambient pressure. 4) PE 63, PE 80, PE 100 5) Depending on the preheating 6) LEISTER empiric parameters 7) Welding rod has to be pre-dryed Please note: The indicated welding parameter may vary depending on the ambient temperature and the material configuration. Test welds need to be done and the parameter aligned accordingly! Leister takes no responsibility for poor quality welding! Based on DVS 2207-3

1) Measured 5mm in the nozzle, in the centre of the nozzle opening.

2) Drawn-in cold air volume at the ambient pressure. 3) Depending on the welding filler material diameter and the welding groove geometry. 4) PE 63, PE 80, PE 100 5) Nitrogene recommended 6) LEISTER empiric parameters Please note: The indicated welding parameter may vary depending on the ambient temperature and the material configuration. Test welds need to be done and the parameter aligned accordingly! STANMECH takes no responsibility for poor quality welding!

We've written previously about the Advantages of a Screw Extruder for Extrusion Plastic Welding. In a screw-based extruder, the turning screw grinds up the welding rod as it passes through the barrel. Both the mechanical energy of the turning screw and heat introduced along the extrusion barrel plasticize the incoming material. The barrel can be heated either with hot air or with a coil heater.

Screw Extruder with Hot Air Heating (e.g., FUSION)

This initial operation video shows you—in an easy and simple way—how to set up a Leister WELDPLAST extrusion welder. The video also demonstrates how to maintain the machine in a few steps, as well as safe and secure handling of the machine.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: