|

We've written previously about the Advantages of a Screw Extruder for Extrusion Plastic Welding. In a screw-based extruder, the turning screw grinds up the welding rod as it passes through the barrel. Both the mechanical energy of the turning screw and heat introduced along the extrusion barrel plasticize the incoming material. The barrel can be heated either with hot air or with a coil heater.

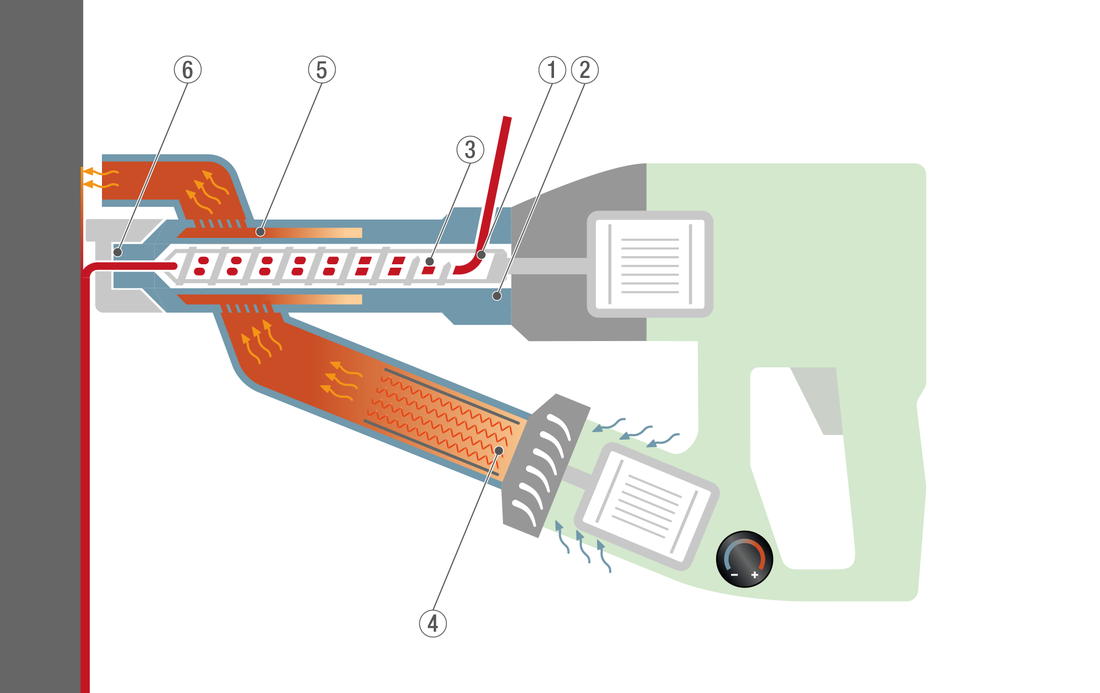

Screw Extruder with Hot Air Heating (e.g., FUSION)

Both types of screw extruders operate with the same principle, the welding rod is pulled into the moving screw (1). In the process, it passes a feed-in sleeve (2) which prevents the rod from twisting. Once inside the screw, a knife (3) cuts the welding rod into small pieces. The screw moves the rod forward, producing heat through compression and friction. An air heater supplies hot air to preheat base materials before welding (4).

In air heated models, the hot air supplied for preheating is allowed to flow around the extrusion barrel in the preheating chamber (5). Combined with the frictional heat of the screw, this causes the welding rod to be plasticized and mixed into a homogeneous mass. The extrudate then exits the nozzle (6). This technology gives the FUSION extruder a simple and robust design. Screw Extruder with Coil Heating (e.g., WELDPLAST)

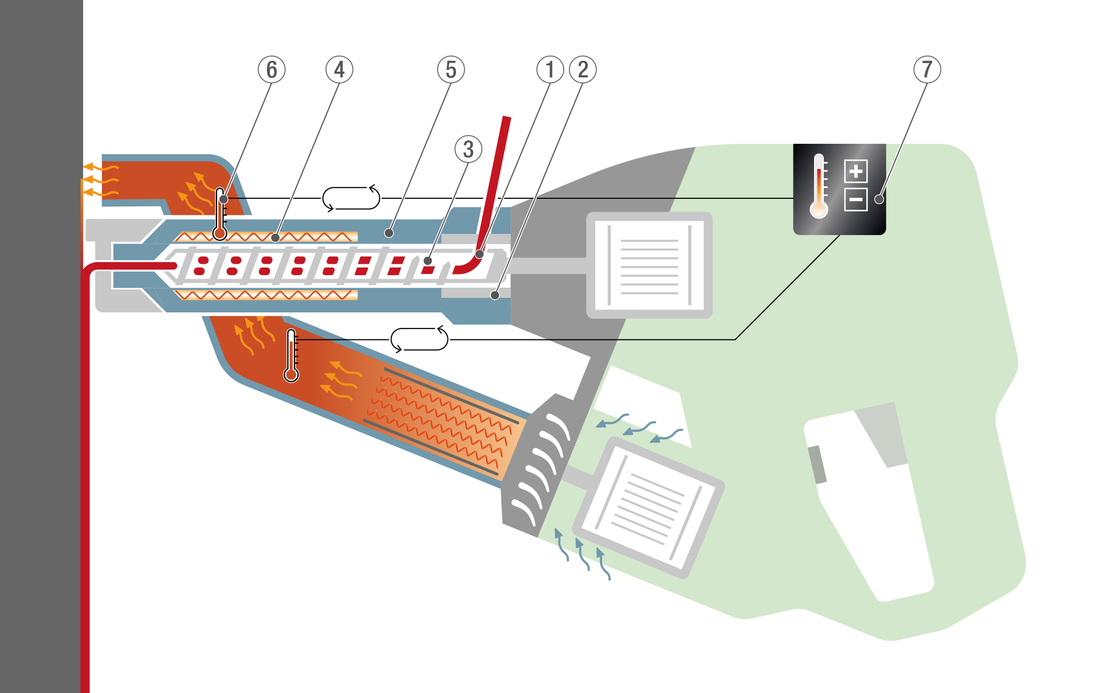

Both types of screw extruders operate with the same principle, the welding rod is pulled into the moving screw (1). In the process, it passes a feed-in sleeve (2) which prevents the rod from twisting. Once inside the screw, a knife (3) cuts the welding rod into small pieces. The screw moves the rod forward, producing heat through compression and friction. An air heater supplies hot air to preheat base materials before welding.

In coil heated models, a coil heater (4) provides the additional heat necessary for plasticization. The heater winds around the entire extrusion barrel (5), a thermocouple (6) built into the barrel measures the plast temperature and relays the information to the control system (7) to ensure the temperature is precisely controlled. The extrudate then exits the nozzle evenly and at a precisely controlled temperature. The preheated air temperature is measured by a separate thermocouple and regulated by the same control system. This technology gives the WELDPLAST more precise temperature control. Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: