|

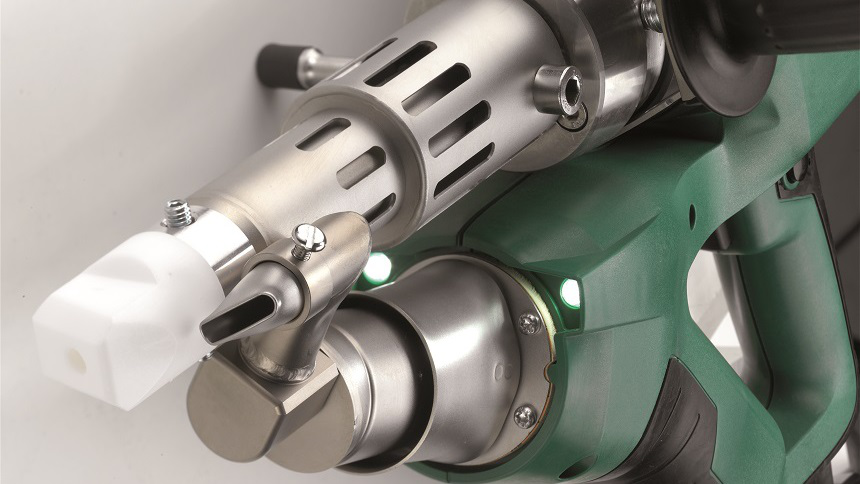

Plastic extrusion welders can generally be divided into two categories: screw-based extruders and non-screw-based extruders.

In both types of extruders plastic material, typically in the form of welding rod, is fed into the unit where it is melted (plasticized) and extruded out the end of the tool.

In a screw-based extruder, the turning screw grinds up the welding rod as it passes through the barrel. Both the mechanical energy of the turning screw and heaters along the barrel of the extruder plasticize the incoming material. Non-screw based extruders use heaters alone to plasticize the welding material. The welding rod is pushed through the heat zone and out the end of the tool but is not ground up in the process. Screw based extruders are the most common and have several advantages: Elimination of Air Pockets in the Welding Rod

Welding rod is not always perfectly uniform and often contains small air pockets. When passed through a screw extruder, the welding rod is ground up as it is heated, allowing many of the air pockets to be eliminated. A non-screw extruder does not grind up the material, meaning those imperfections will be passed through the tool and into your weld

Elimination of Scraping Requirement for Welding Rod

While it is commonly known that the welding area of the base material must be mechanically scraped to remove oxidized and contaminated plastic, it is less commonly known that in certain circumstances the welding rod should be scraped as well. With a screw extruder, the material passing through is ground up thoroughly, meaning it is not necessary to scrape the surface of the welding rod. With a non-screw extruder the material is not ground up, meaning that the surface of the welding rod should technically be scraped to remove any surface oxidation

Temperature Homogeneity

With a screw extruder the material is ground thoroughly as is passes through the barrel. This induces a lot of mixing, meaning you can anticipate a more uniform temperature distribution in your extrudate

More Even Extrusion Rate

Due to the nature of a barrel screw extruder, you should expect a more even flow rate from the outlet of the tool. Non-screw extruders often have a pulsing flow from the outlet and are more prone to slippage of the feed material which can cause an uneven extrusion rate.

For more information about extrusion welders give us a call at 1-888-438-6324 or email [email protected]. Originally published: 07/08/2016 Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: