|

When installed and operated properly, an air heater should have a long service life. However there are many common pitfalls that can cause problems and shorten the expected lifespan. This article discusses our recommended best practices for installing air heaters to avoid the most common errors that shorten tool life.

Hose or Piping

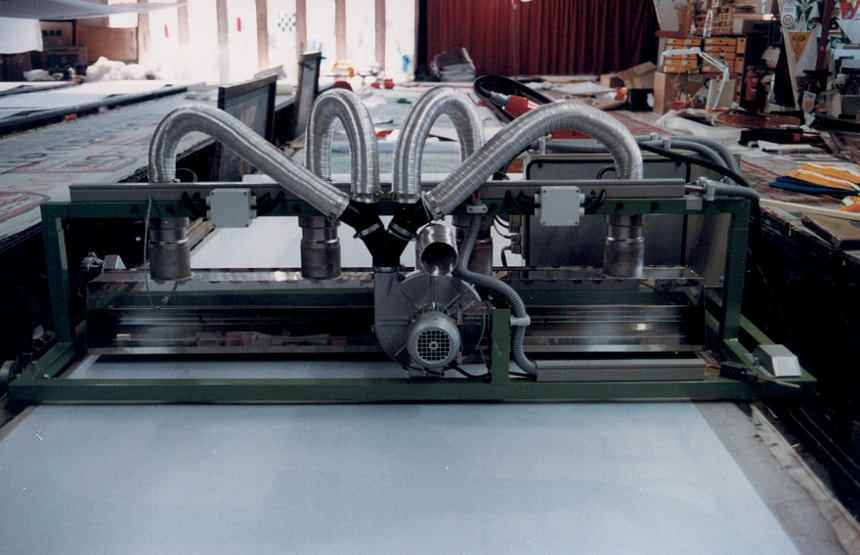

Air is typically supplied to the heater from a blower connected by either flexible hose or hard piping. When making this connection the pressure drop from the blower to the heater must be considered. As the pressure drop increases, the output flow from the blower will be reduced. Read more about pressure drop in blower-based systems. The following are some best practices to keep in mind:

Proximity to Work

After exiting the air heater the air temperature immediately begins dropping with distance travelled. To be sure the heater is working efficiently it should be placed as close as possible to the target without restricting the outlet. Restricting the outlet can lead to reduced flow and potentially damage the heater.

Thermocouple Placement

Thermocouples are not used in all applications but when applicable there are some rules of thumb regarding placement:

Recommended Reading

Originally published 09/24/2014

Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: