|

Hot air systems, at their most basic, combine two components—a stream of air supplied by a blower/compressor and heat generated from a heating element—to produce hot air. Sometimes these two components are supplied by a single tool, other times they are supplied by two separate tools. The goal is to increase the temperature of the stream of air and to use this air for a task. Understanding how air flow and temperature relate to each other is helpful when choosing air and heat sources for your system to ensure your system will be able to do the work required.

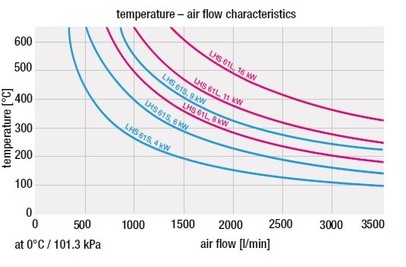

Raising the temperature of air requires energy; the amount of energy required depends on the volume of air and the magnitude of the temperature increase. Air heaters are rated by power in watts or kilowatts which specify the energy that the element is capable of applying per unit of time. See our article on The Basics of Heat Calculations for further explanation. There is an inverse relationship between air flow and temperature. For example, if the air flow over the element increases then one of two things happens: to maintain a constant temperature the element must increase its power output or the temperature of the output air will be lowered. Why is this important?

This becomes important when choosing a heater and blower combination. Air heaters have a temperature-air flow curve associated with them as shown below:

Each heater has a curve, with power kept constant. This curve shows the maximum temperature the heater can attain at a given air flow. When designing a process heat system, this curve tells us the air flow range at which the heater can maintain a target temperature. It also indicates the minimum air flow required to prevent damage to the heater (i.e. the airflow at which the maximum rated temperature for the heater is reached). This chart allows us to size an appropriate blower for a heater in order to operate at our required temperature or to size a heater (in kW) for a required air flow.

Confused about the distinction between temperature and heat? Read our article on the difference between these two common terms. Still have questions about sizing your heater and blower? Call STANMECH and let us help you. Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: