|

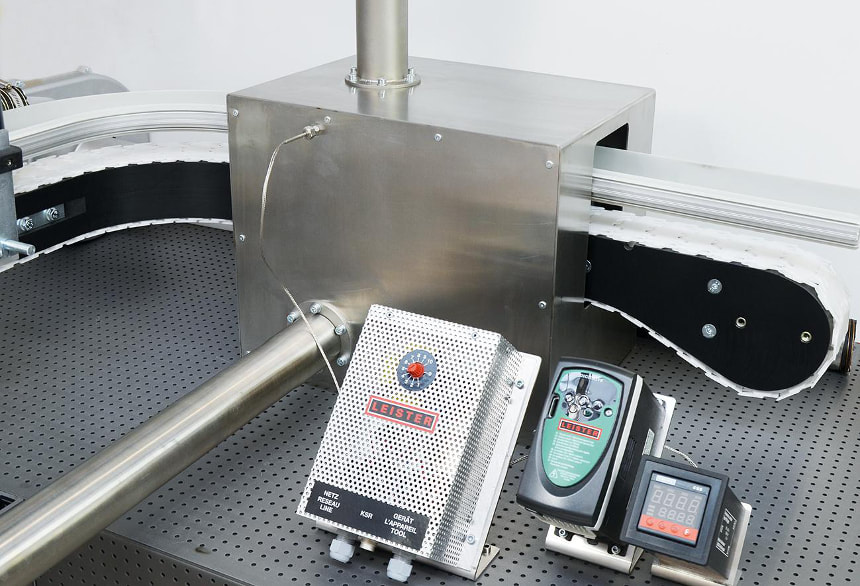

In an air heater, air is blown over a resistance coil which is heated by a voltage applied across it. The temperature control of the air at the outlet of an air heater depends on the level of sophistication of the heater and any control systems with which it is integrated. Before discussing air heater control, first we will take a very high level look at system control.

Every plastic has a set of parameters (temperature, pressure, time/speed) at which it should be welded. However, the perfect temperature for the application can vary depending on environmental conditions. If you are welding in a less than ideal environment, the only way to find the perfect welding temperature for your project is trial and error. If welding is taking place outdoors be sure to perform test welds periodically throughout the day to ensure your temperature is set correctly, as the environment can change over time.

Patching is a quick and economical way to prolong the life of tents, tarps, and other items made from industrial fabrics.

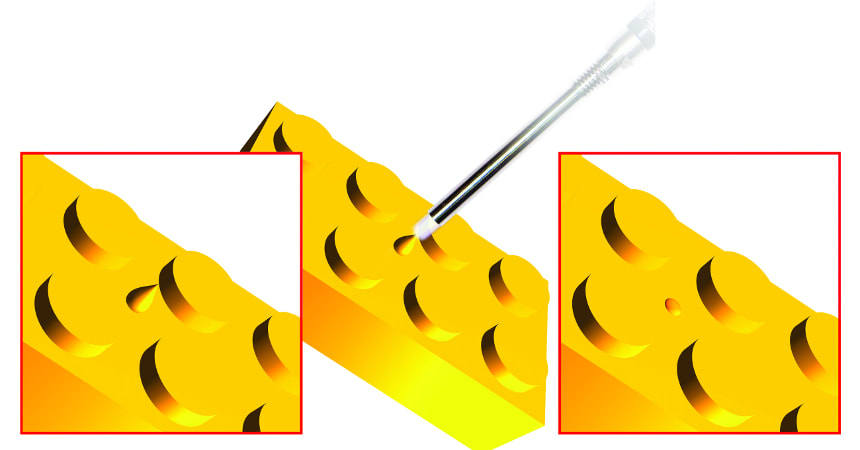

Injection moulding is one of the most common industrial methods for high volume production of plastic parts. Plastic is heated until it reaches a thermoplastic state and is then injected into a mould. During this process a seam can develop on the part where different segments of the mould meet, known as the parting line. This seam of excess plastic is called flash. Flash must be removed from the part when it occurs in an area where surface finish is important or where it will cause an interference.

Receiving an error message while on the roof can be extremely frustrating. Below you’ll find the common error codes you may encounter and an explanation of what they mean.

The hallmarks of a bad shrinking job are easy to spot: wrinkling, rising, dimpling, tearing and uneven shrinking. These problems drive packagers nuts and can put off potential customers. Read on to discover possible causes and solutions to the most common problems facing packagers working with shrink labels.

It’s important to evaluate each plastic weld to ensure your final product is strong and resilient. Particularly when speed welding with a hand tool, small defects in a single weld can be magnified as beads are built up to the base material’s thickness. Several key indicators allow you to evaluate your welds without the need for destructive tests.

Welding fabrics by hand is an easy and inexpensive way to complete small jobs, build prototypes, or complete repairs either in the shop or the field.

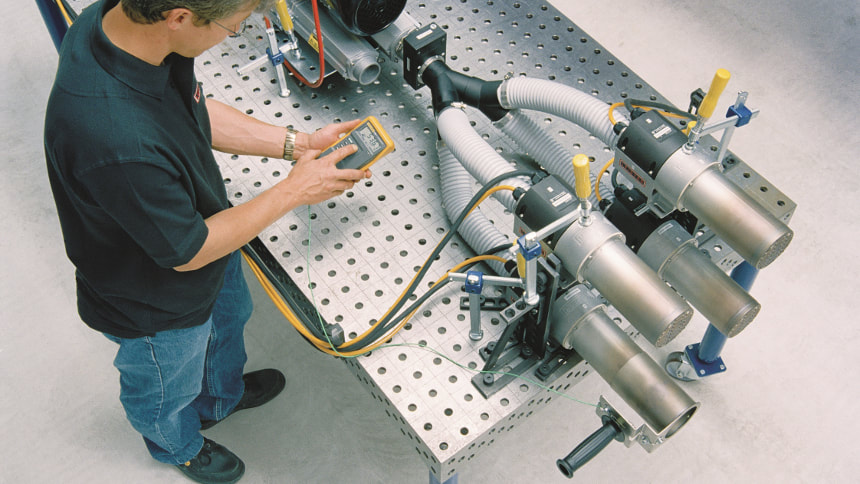

Variable Frequency Drives (often known by their initials: VFDs) convert a fixed-frequency supply voltage (60 Hz in North America) to a continuously variable frequency. By controlling the frequency of the voltage supplied to an AC motor, we can control its rotational speed and minimize stress. A VFD can control two main elements of a 3-phase induction motor: its speed and torque.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: