|

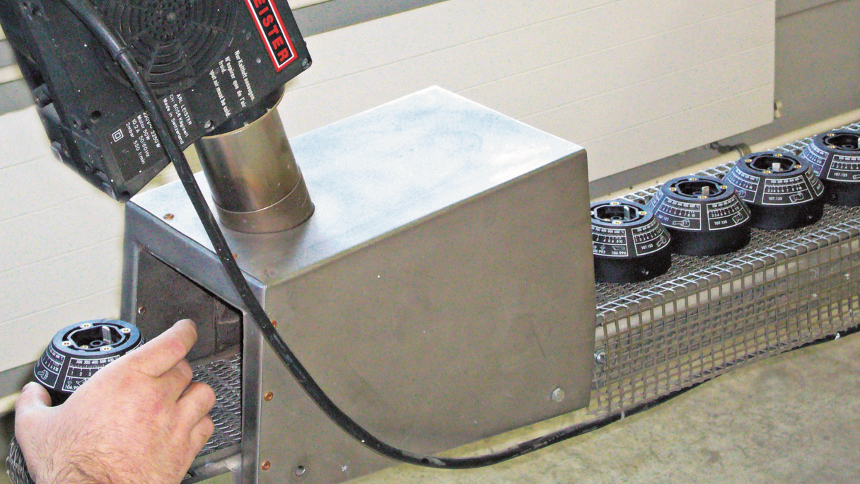

Achieving a watertight weld on geomembrane material is all about finding the correct balance of parameters: temperature, speed, and pressure. Leister has produced the below chart as a handy starting point for welding with their geomembrane equipment. Be sure to conduct test welds before commencing.

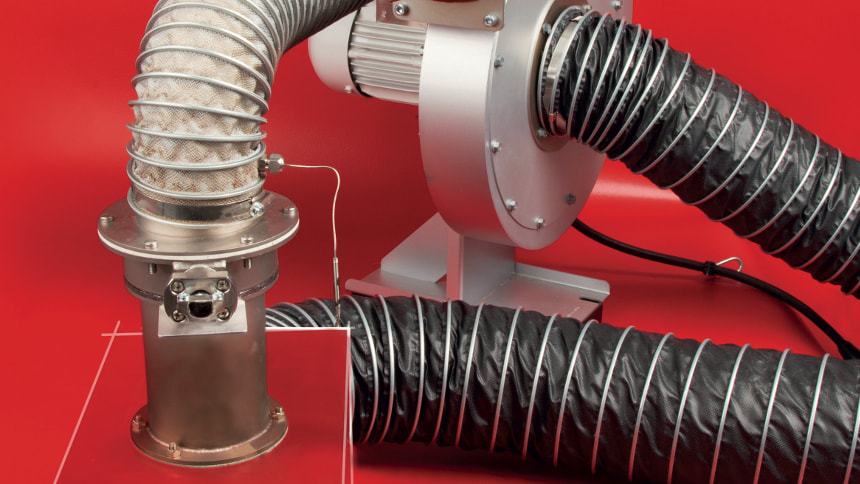

One of the most common application enquiries we get at STANMECH Technologies is about using air heaters to create an oven. Creating an oven is a logical use of air heaters but there are a few areas that require technical knowledge to ensure your oven achieves the desired end result. Below, we cover the 5 areas that require consideration when using hot air to create an oven.

When the temperature begins to dip, welding roofing material takes on special challenges. Here are our tips to ensure a watertight weld in cold weather.

Leister’s industrial air heaters are very robust but there are times when they show troubling symptoms. This application note outlines some of the most common symptoms that you might see and how to go about solving the underlying problem.

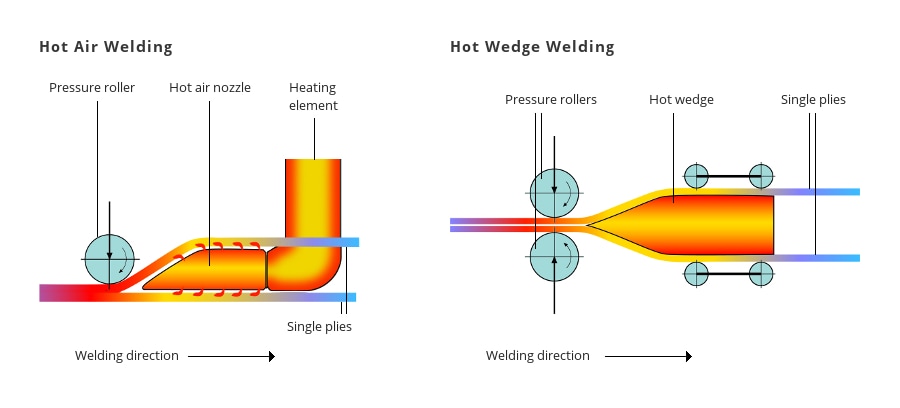

Plastic welding requires three essential things: temperature, pressure, and time. Without all three plastics may be bonded but will lack the strength of a weld. When done properly, a plastic weld will be as strong as the surrounding material.

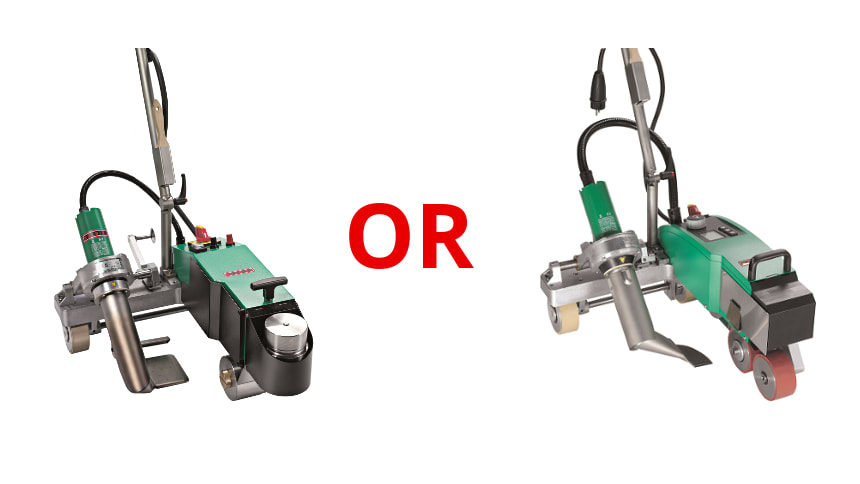

The main difference between a wedge and a hot air welder is the way in which heat is transferred to the material. With a wedge welder, a solid piece of metal—the wedge—is heated and inserted between the two pieces of material. With a hot air welder, air is heated and then delivered between the two pieces of material via a hot air nozzle.

We often get requests from customers for assistance building a heat solution for drying or adding heat to an existing drying system that is under-performing. This is understandable, using heat to dry is a common occurrence in our everyday lives from clothes dryers to hair dryers. In this article we explore why hot air is not always the best drying solution and talk about using fast moving air as an alternative to heat. We also give guidelines to help you decide when to use heat and when to only use air.

We often get questions from customers about the VARIMAT V2 and the BITUMAT B2. These machines seem similar on paper but are specialized to deal with specific roofing materials.

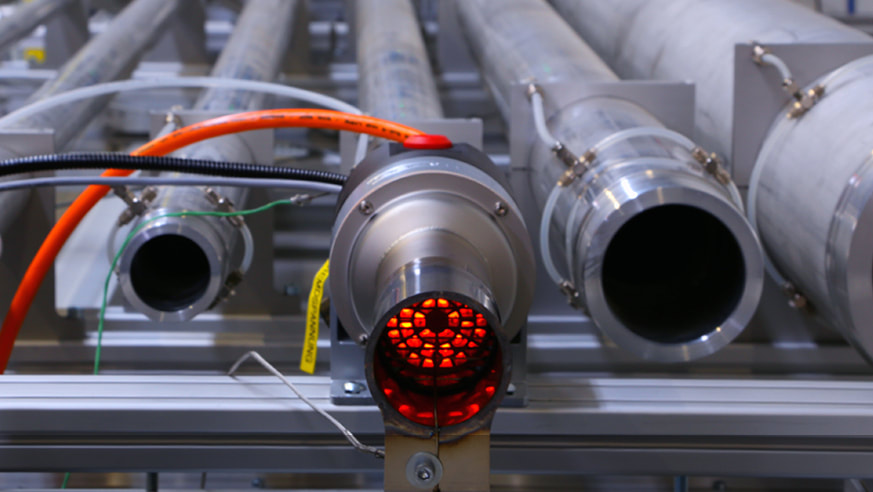

Thermocouples are widely used to measure temperature in industrial processes. In this article we will explain how a thermocouple works, when you should use one, and some best practices for use.

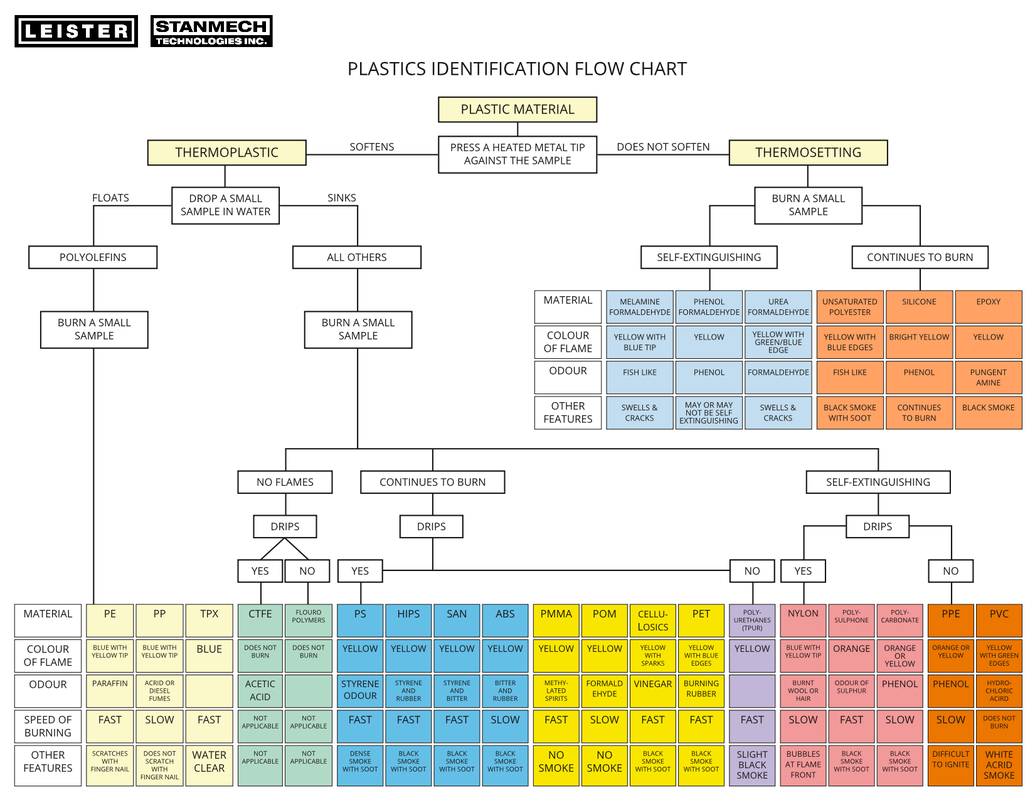

Knowing which type of plastic you're working with is a cornerstone of good plastic welding. By asking you to perform a few simple tests, such as a flame or burn test, the flow chart below will help you determine which type of plastic you have.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: