|

We often get requests from customers for assistance building a heat solution for drying or adding heat to an existing drying system that is under-performing. This is understandable, using heat to dry is a common occurrence in our everyday lives from clothes dryers to hair dryers. In this article we explore why hot air is not always the best drying solution and talk about using fast moving air as an alternative to heat. We also give guidelines to help you decide when to use heat and when to only use air.

What does “drying” mean?

Firstly let’s clarify what drying can mean. The term is used in many ways that can be open to interpretation. The term “drying” is commonly used to describe all the following applications:

In some cases the term “drying” is misused and it would be more correct to say curing. Regardless of the terminology, the important point is that not all of these applications are good candidates for using heat to accomplish the end goal. When to use heat and when to use air

Drying applications can be divided into three categories: blow-off, evaporation, and curing. Here we are going to lump evaporation and curing into a single category because, although the underlying chemistry is different, the possible solutions for the two are the same.

Blow-Off

Many manufacturing processes leave a significant amount of excess liquid on a surface that needs to be removed. It is much more efficient to mechanically remove the liquid rather than attempt to evaporate it from the surface. In order to evaporate the liquid, enough energy needs to be applied to raise the volume of liquid from its starting temperature to the boiling point temperature and to change the state from liquid to gas. The number of Watts (units of energy per unit time) required for the heater to evaporate the liquid in a practical timeframe quickly escalates. In these scenarios, blow-off has the advantage of being fast and energy efficient. The outlet of a blower is connected to an air knife to focus the air into a fast moving sheet. The impingement of the air on the surface then literally strips off the liquid.

See our article on The Basics of Heat Calculations for more details. Evaporation/Curing

Applications where evaporation and/or curing need to take place require the introduction of heat. Examples include drying paint, drying ink, or curing epoxy. In the cases of drying paint or ink, the final surface finish is important; fast flowing air would not only damage the surface but would likely strip the paint right off the surface. In the case of epoxy, and some paints, the heat also acts as a catalyst to the curing process.

Hybrid Solutions

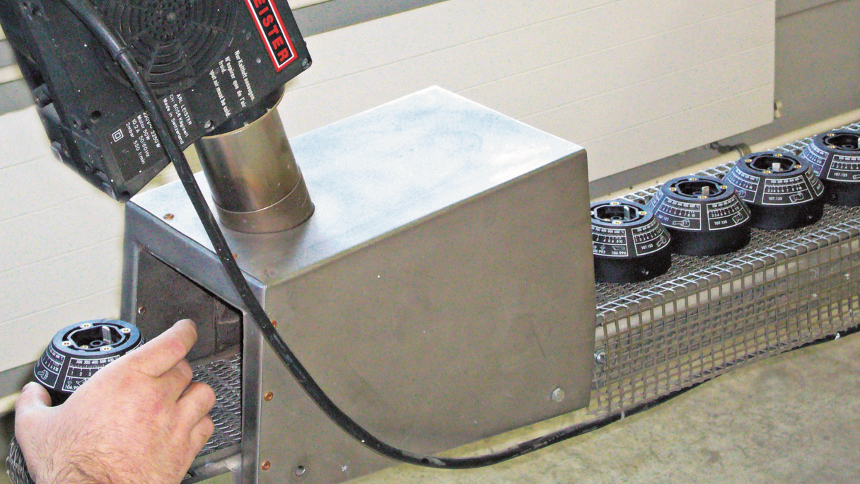

There are times when the optimum solution to a problem is a combination of heat and air. Every application must be evaluated separately but below are some examples of ones that lend themselves to a hybrid solution.

Drying problems may not be as straight forward as they first appear. At STANMECH Technologies we have a great deal of experience in the design of blow-off, heat, and hybrid systems. Contact us to discuss the best solution to your application. Originally published: 03/20/2015 Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: