|

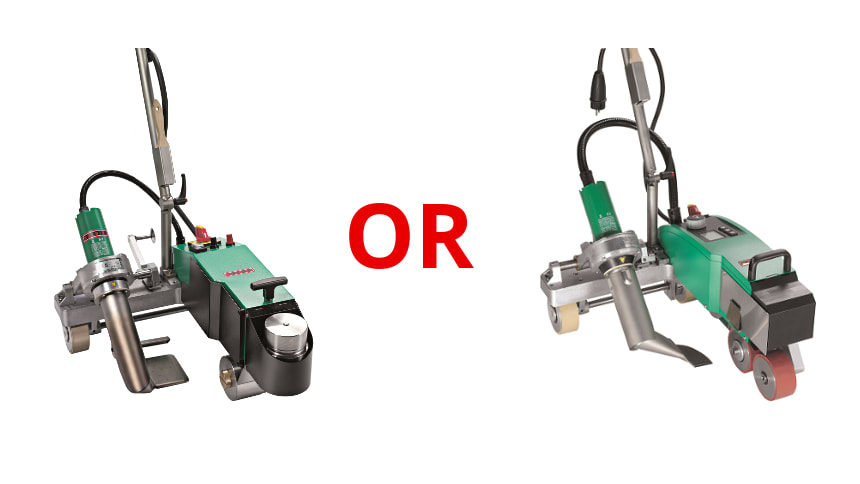

We often get questions from customers about the VARIMAT V2 and the BITUMAT B2. These machines seem similar on paper but are specialized to deal with specific roofing materials.

Similarities

The VARIMAT V2 and BITUMAT B2 are both designed for flat roof work and are best suited for basic welding seams, not detail work. They perform exceptionally well on long, straight runs. They have similar drive speeds, dimensions, and looks and they both achieve their welds using hot air. Beyond this, the tools have little in common.

Differences

The largest difference between the VARIMAT V2 and BITUMAT B2 is the material they are designed to weld. The VARIMAT V2 is made exclusively for use on single ply thermoplastic materials whereas the BITUMAT B2 is made exclusively for use on modified bitumen. Although a popular request, one machine cannot weld both materials.

The welding seam width that each tool provides is optimized for the material as well. The VARIMAT V2 welds 40 mm seams while the BITUMAT B2 welds 75 or 100 mm seams, depending on the model. The BITUMAT B2 carries an extra 5 kg (11 lbs) of weight and has a slower top welding speed of 6 m/min. (19.6 ft./min.). The BITUMAT B2 has a power output of 6700W while the VARIMAT V2’s output is 4600W. This added power output, along with the heavier machine, allows the BITUMAT B2 to handle the more difficult task of welding modified bitumen. Other aspects of the tools like the nozzle design and pressure roller material are optimized for the material as well. Have questions about these tools? Contact your Technical Sales Representative for more information. Originally published: 09/14/2015 Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: