|

Whether large, small, with sugar, milk or foamed milk, black and strong, traditionally at home, at work, on the go or consumed in a café. Coffee is the second most common consumed drink after water worldwide. Read this blog post to find out what connects PROBAT, Leister and coffee.

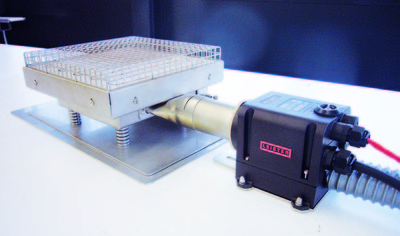

For the recent development of a line of machines for spray painting and drying closures, both in plastic and aluminium, Omso has adopted the heaters produced by Krelus, a company of the multinational Leister group.

Modern plastics have become a part of our everyday lives. One can even go as far to say plastics consumption is a benchmark for measuring how developed a country is. According to Plastics – the Facts 2014/2015, a report published by PlasticsEurope, “...plastics materials have been key enablers for innovation and have contributed to the development and progress of society.”

MEAF Machines B.V., a manufacturing company based in Yerseke, Netherlands, produces sheet extrusion machines and deep drawing machines for roll material (inline thermoformer). The company›s strengths include supplying turnkey production lines.

When one of MEAF›s customers was interested in purchasing a new production system for optimizing its production process of packaging sheets for foodstuffs containers, it immediately referred MEAF to Leister. The customer already had a good experience with an existing equipment line equipped with Leister LE 10000 air heaters and Leister SILENCE blowers. The planned new production system was intended to significantly increase production capacity but also to reduce production costs. Consequently, the representatives from MEAF suggested equipping the new machine with an antiblock applicator. Problem

A chocolate maker was having trouble with roughness left on the bottoms of their moulded chocolate bars. Their process involved melted chocolate being poured into bar shaped moulds and smoothed with a rubber doctor blade. Unfortunately, this smoothing motion left the bottom side of the chocolate bars rough and unattractive resulting in high reject rates and poor quality. The Coca-Cola Bottling plant in Downey, Ca had been having difficulties with wet beverage cans, resulting in illegible lot/date codes on the cans and “can bursts” that caused ruined packaging and unsaleable pallets of product. Coke had a compressed air system in place that was not only doing an inadequate job drying but it was inordinately expensive in energy costs. To address these problems, Coke contacted JetAir Technologies. JetAir, in Conjunction with WahlWorks Engineering, designed a drying system using the JET-2 High Speed Centrifugal Blower and unique JetAir JetBlast nozzles.

Introduction

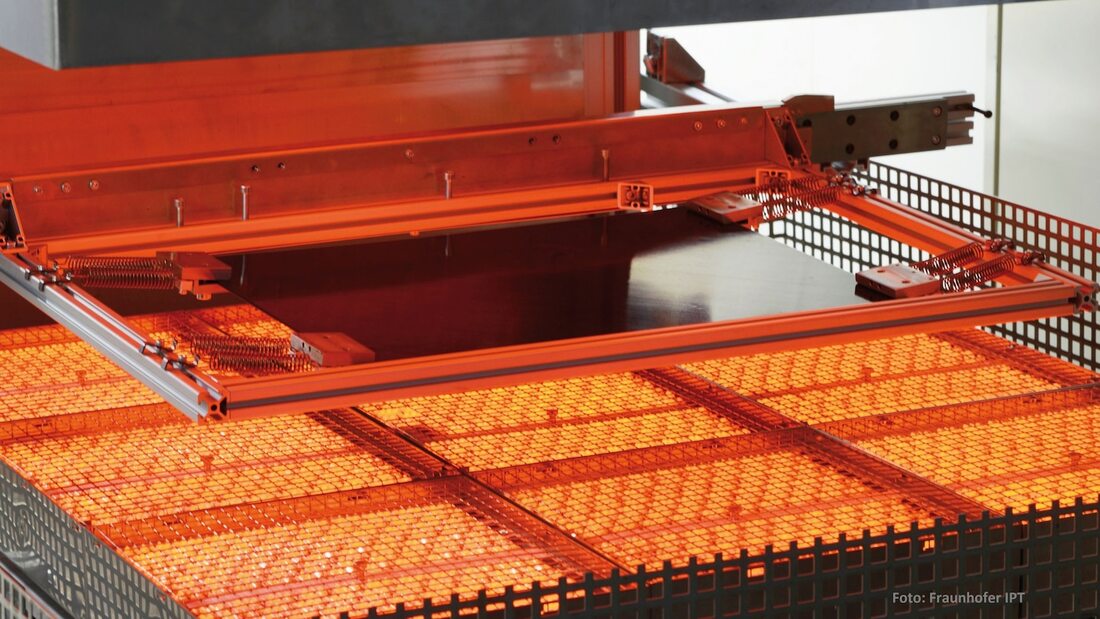

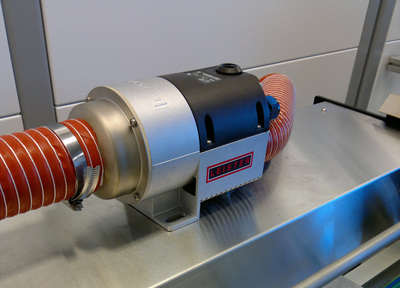

Rising energy costs and growing concern for industrial environmental impact has manufacturing taking a second look at their operations' energy efficiency. One area increasingly under review is the use - or more importantly, the misuse - of compressed air. When used "inappropriately" (as defined by the Department of Energy's Compressed Air Challenge), high pressure compressed air bleeds into the atmosphere producing a significant energy loss, as well as a comparably high demand on compressor utilization. With a price tag of $1.5 billion in U.S. manufacturing compressed air energy costs each year (according to the Department of Energy), compressed air alternative solutions, such as high-speed, centrifugal blowers, represent a significant energy and cost saving option for manufacturers. Recently, a major U.s. soft drink bottler replaced their compressed air system with a JetAir Technologies high-speed centrifugal blower system realizing an 87% true energy power savings and an 80% energy cost saving, as well as a return of compressed air compressor capacity. Renewable energies are on everyone’s lips. They are set to cover an increasing share of the energy mix in the future. Besides wind and water, photovoltaics (PV), is becoming ever more important among renewable energies. A cost reduction in PV modules is also playing a significant role in helping photovoltaics in becoming even more widespread. This is due to increasing unit volumes and continuous improvements in production techniques. One of the many steps in the production of PV modules involves drying the silicon wafers after cleaning. Here, the drying time on the production lines of the Norwegian special machinery manufacturer, Tronrud Engineering, could be reduced thanks to the use of Leister air heaters. As a result, the entire cycle time for the production of PV modules could also be considerably shortened. Click image to enlarge.

The Achievement

Condensation that formed on bottles after cold-filling was causing problems for Eska Eaux Vives Water in Quebec. Issues included problems with label adhesion and damage caused by the water to boxing and packing materials. With the introduction of a state-of-the-art blower and air knife system from STANMECH Technologies Inc. the bottles are now dried completely before transparent labels are applied and the bottles are packaged and shipped.

Click image to enlarge.

JetAir Provides Kroger “Clearly Superior Equipment” for improved performance and cost savings11/4/2010

JetAir was contacted by the Facilities Engineering team at Kroger Bakery in Indianapolis, IN about a replacement for their costly compressed air blow-off system. A member of the team was familiar with JetAir technologies through reputation and past experience.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: