|

Whether large, small, with sugar, milk or foamed milk, black and strong, traditionally at home, at work, on the go or consumed in a café. Coffee is the second most common consumed drink after water worldwide. Read this blog post to find out what connects PROBAT, Leister and coffee.

2.6 billion cups of coffee are consumed worldwide every day. After oil, coffee is the second most frequently traded raw material in the world. Why are we at Leister interested in coffee? Because the German company PROBAT plants of Gimborn Maschinenfabrik GmbH, world market leader in machinery and systems for the coffee and food industry, has now developed their first P-Series shop drum roaster with electric Leister hot air solution.

If you are looking more intently at the aromatic pick-me-up, you can quickly find out that coffee roasting is an art. All over the world, roast masters deal with roasting coffee so that it tastes particularly good and, above all, has a uniform taste. There is even a World Championship in coffee roasting called World Coffee Roasting Championship. Market and technology leader PROBAT has over 150 years of experience in the production of roasting machines

Over four generations, the company PROBAT in Emmerich, Germany, has become the market and technology leader in the manufacture of roasting machines for industry and for stores. PROBAT is a global brand. Roasters, products and solutions from PROBAT can be found on all continents and in all renowned roasting companies.

What to look for when roasting coffee

The amino acids and sugar acids contained in coffee beans are completely reconstituted during roasting. This can produce up to 1000 aromas from one cell. The roasting process thus gives the coffee its special aroma.

Various coffee roasting machines

In order to roast the green beans in an aromatic way, PROBAT has developed the following different roasting machines: Shop Roaster, Drum Roaster P60, Drum Roaster Px 120, Drum Roast Neptune, Tangential Roaster Jupiter and Centrifugal Roaster Saturn.

These roasting machines are segmented based on the respective roasting process and their so-called batch size, i.e., how many kilograms/pounds of coffee they roast in one run. PROBAT laboratory roaster equipped with Leister MISTRAL 6 SYSTEM air heater

Heating with gas or electric hot air

Whether drum roasters, tangential roasters or centrifugal roasters, today most coffee roasting machines are operated with gas, with a few exceptions. However, in connection with climate protection, sustainability and legal requirements, alternative heating methods are increasingly attracting interest. However, no electrical heating system has been found so far that permits a roasting process that is close to that done with gas. Why is that? Compared to gas-powered roasters, the earlier electrically heated roasters are considered to be sluggish.

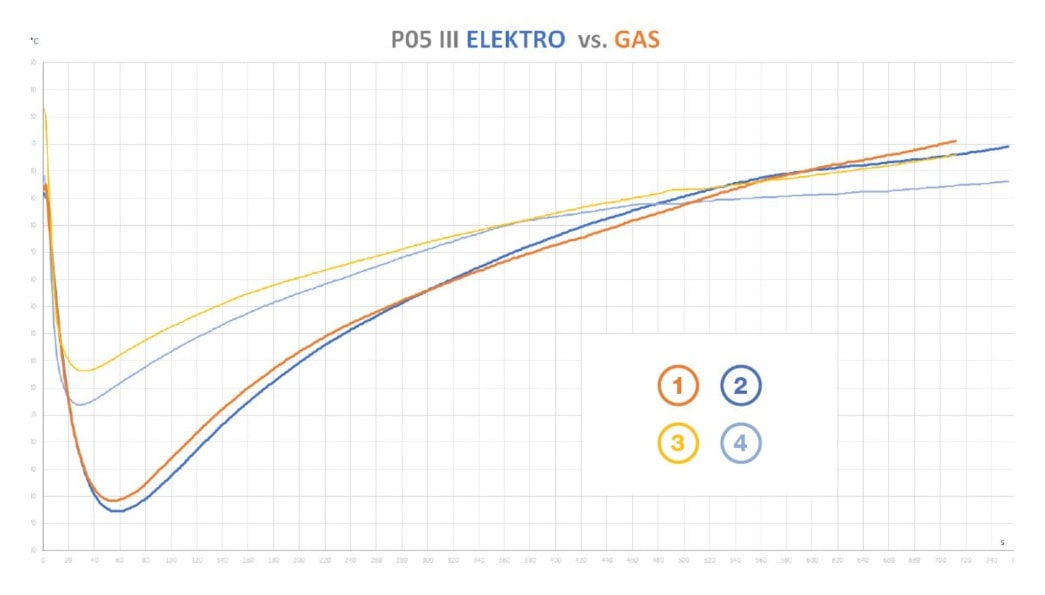

In this context, sluggish means that the roasting curve rises not fast enough after the “turning point”. This is because the temperature of the electrically generated hot air is too low. This makes it impossible to follow the roasting curve specified by the roast master in order to achieve a repetitive, i.e., continuously uniform roasting from batch to batch. And that is exactly what is essential when roasting coffee, because the aroma of the coffee should always be the same. After all, customers buy their coffee because it has the aroma they like. And they don’t want their coffee to taste different every time. It is a matter of the right roasting curve

As mentioned, the roast masters are artists who have a lot of practical experience. The roasting recipes they create are roasting programs with which a specific coffee with its very typical aroma is repetitively produced with the roasting machine. The core of the recipe is the “target bean temperature curve” during the entire roasting time.

The graphic (graphic source: © PROBAT) shows clearly how the temperature first drops after the beans to be roasted are filled in. The master roaster naturally has taken this into account in the roasting program.

Software controls the parameters of the machine. These are burner power and thus burner temperature, air flow, drum speed and initial temperature, which must follow the roasting curve specified by the master roaster very precisely. This up to an accuracy of (+/- 0.5 degrees). These process guarantees the reproduced production of the same desired coffee quality. PROBAT and Leister develop an electrical heating system for the shop drum roaster P05

In search of an alternative for the gas heating of the shop drum roaster P05, PROBAT approached Leister. The idea was to collaborate to develop an electrical heating system that works. And it worked out. Together, PROBAT and Leister have replaced the existing 14 kW gas heater on the P05 Drum Roaster with a 17 kW electric heater from Leister. In addition, the control of the heating system was modified and the process optimized.

A milestone in the development of shop drum roasters

In addition, the P05 e Drum Roaster can be installed very easily and quickly compared to a drum roaster heated with gas. And it may be set up anywhere gas is prohibited. For example, in shopping centers, in event catering and in other places where open fires are not permitted.

Dietmar Wißen, Development Project Manager for Research & Innovation at the PROBAT plants of Gimborn Maschinenfabrik GmbH, is enthusiastic about Leister’s electric hot air solution: “The P05 Drum Roaster with Leister electric air heater can be controlled just as flexibly as a gas burner and enables the same high roasting quality.” Stephan Rüegg, Business Development Manager of Process Heat at Swiss Leister Technologies AG, is also delighted: “It fills us with pride that, together with PROBAT, we have found an environmentally friendly solution for heating the shop drum roasters with hot air. This solution offers a good alternative to gas for all master roasters who care about our environment as much as Leister.” Many thanks

We would like to thank PROBAT for the order and for the trusting and good collaboration in this exciting project.

PROBAT kindly provided us with the images and graphics in the blog post (image and graphic source: © PROBAT). Thank you very much for your permission to publish our joint success story.

Author: Silke Landtwing, Manager of Corporate Communications, Leister Switzerland

PROBAT PLANTS WEBSITE FOR GIMBORN MASCHINENFABRIK GMBH Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: