|

In rural Vietnam and many other areas of Asia, people still cook with fossil fuels, such as bottled gas. Read this article to find out how Leister is supporting an international research team in its search for a more environmentally friendly alternative.

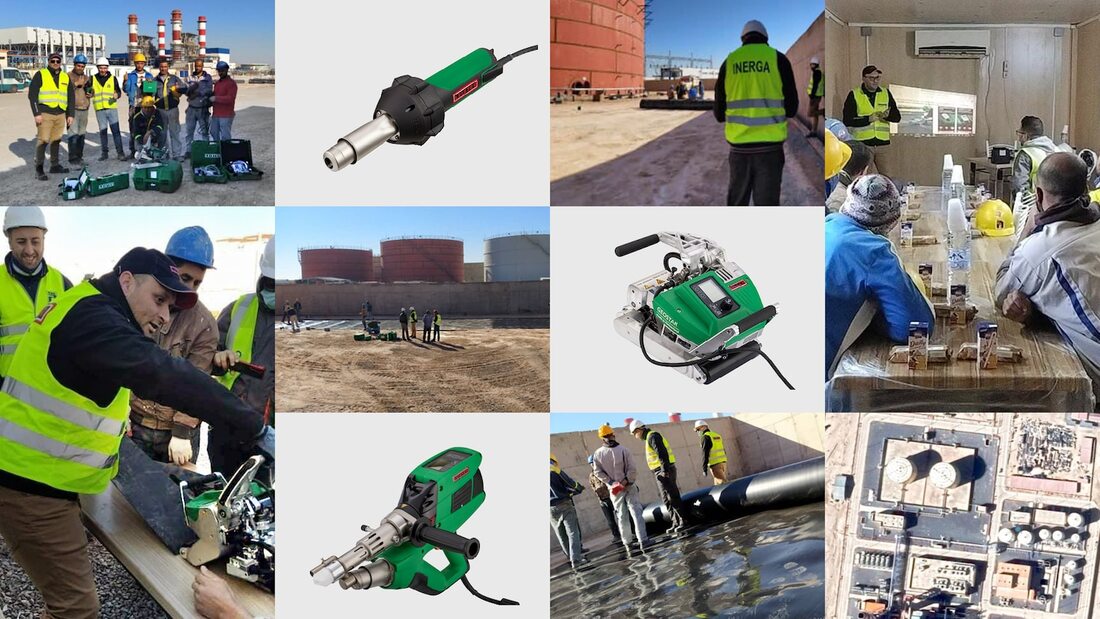

The Algerian company Inerga is now independently completing large geo projects thanks to the excellent cooperation with Leister's Algerian distributor, ChimiBat. Read more in this blog post.

The successful Leister distributor, RIKAZ, sells Leister equipment for plastic welding in Kazakhstan. In this blog post, we discuss how Leister’s automatic welding machines are used to weld the geomembranes on large gold mine, tailings ponds. Tight weld seams are also crucial here to ensure that no contaminated water enters into the soil or groundwater.

In India, a railway line is being built to connect the city of Baramulla in the Kashmir Valley with the rest of the country. For this purpose, numerous tunnels have to be drilled and sealed. Various Leister devices and machines are used for this purpose.

An important sector of the Indian economy is agriculture. This is where 60 percent of the population works and generates about 17 percent of the gross domestic product. India has the tenth largest arable resources in the world with 20 agro-climatic regions.

The Moroccan company, Smart Irrigation, based in Marrakesh, the pearl of southern Morocco, successfully develops challenging projects for the sustainable use of scarce water resources in North and West Africa. Examples of such projects by Smart Irrigation include installing water basins for plantation irrigation systems in which olives, lemons and mangoes thrive. Especially in North Africa, everything revolves around the best possible protection and use of scarce water resources.

Montenegro is a small, mountainous country with 800,000 inhabitants. And it is the only country in the Balkans which does not currently have any freeways of its own. This creates an economic problem as it hinders tourism along the Adriatic coast and makes it difficult to access various parts of the country. Thankfully, a solution is on the way and will be ready in four years' time.

According to Lu Shan, Chairman of the China Road and Bridge Corporation (CRBC), the construction of the first freeway section between Smokovac and Matehevo is set to be completed by 2020. CRBC is heavily involved in the implementation of the project, which is also being largely financed by Chinese funds. The plan is to complete the entire road infrastructure project by 2022. A mammoth project

In order to connect up the new freeway network, which will snake its way all over Montenegro, 42 tunnels and 92 bridges/viaducts will need to be built. The tunnels are scheduled to be finished by 2020.

Tunisia is Africa's northernmost country, with a coastline along the Mediterranean Sea to the north and east, and two bordering countries: Algeria to the west and Libya to the south-east. Spanning some 163,610 km², it is approximately twice the size of Austria. Tunisia boasts a highly competitive economy and a population in excess of ten million.

First Road Tunnel Project – Sealed Using Geosynthetics

In an effort to stimulate its economic and social development, the Republic of Tunisia is making investments in its road infrastructure. For the first time in the country's history, this is involving the construction of a road tunnel featuring state-of-the-art sealing work that uses geosynthetics.

Over a total length of 3 km, the intention is to link the GP10 and X thoroughfares in the Tunis and Ariana regions by means of four tunnels – with four lanes. The tunnels in this case are covered trenches whose length stretches over 1.2 km in total. Construction is scheduled to be completed within 30 months. The project aims to not only establish an improved link between the city of La Soukra and the main Tunis arteries, but also reduce the volume of traffic at Tunis-Carthage International Airport and on the major roads that surround it. This large gold mine in Mexico is the perfect environment for the WELDPLAST S6 extrusion welder from Leister. The high output of 6kg/h (13 lbs) is an fast solution for the lining of heap leach pads, lakes or landfills. This large gold mine in Mexico was the perfect challenge for the new GEOSTAR wedge welder from Leister. The high welding speed of the GEOSTAR wedge welder is an economic solution for the lining of heap leach pads, lakes or landfills. With high quality equipment and friendly Leister service, users experience maximum productivity even under extreme environmental conditions. |

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: