|

Renewable energies are on everyone’s lips. They are set to cover an increasing share of the energy mix in the future. Besides wind and water, photovoltaics (PV), is becoming ever more important among renewable energies. A cost reduction in PV modules is also playing a significant role in helping photovoltaics in becoming even more widespread. This is due to increasing unit volumes and continuous improvements in production techniques. One of the many steps in the production of PV modules involves drying the silicon wafers after cleaning. Here, the drying time on the production lines of the Norwegian special machinery manufacturer, Tronrud Engineering, could be reduced thanks to the use of Leister air heaters. As a result, the entire cycle time for the production of PV modules could also be considerably shortened. Click image to enlarge. Photovoltaics as an engine for growth

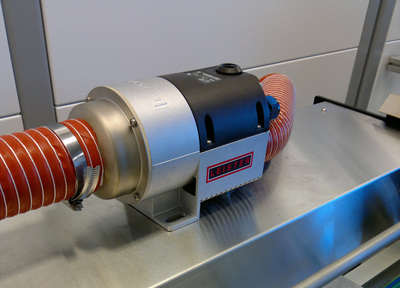

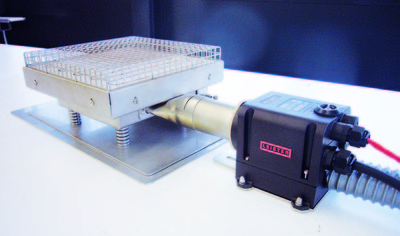

At the Norwegian machinery and plant manufacturer Tronrud Engineering, air heaters of the LHS product line from Leister are used for sensitive drying processes in the wafer processing. Tronrud is one of the largest special machinery manufacturers in Scandinavia. Amongst other things, the company is specialized in complete production lines for the production of silicon wafers. This segment of business has enjoyed above-average growth in the past few years, driven by rising demand in the photovoltaic market. Tronrud Engineering has developed into one of the leading suppliers to the world’s largest wafer manufacturers. The Norwegians provide the PV industry with a broad spectrum of flexible production modules for various processes. These modules can be combined into completely automated production lines or — depending on requirements — also operated as stand-alone systems. An example of an automated production line can be seen in Picture 1 (below), the “Wafer Inspection Line (WIL).” The WIL carefully performs all steps from the sawn block through to the packed wafer. It achieves an availability of more than 95 percent as well as a fracture rate of under 0.5 percent, – all within a cycle time of once second per wafer! Hot air as an accelerator These impressive values can also be attained thanks to the drying technology used. After the obligatory fine washing of the individual wafers, the moisture is removed without a trace in a drying tunnel. The wafer must be completely clean and dry for the downstream processes. First, a portion of the wash water is blown away before the tunnel using a sharp blast of air – also referred to as an air knife. To prevent damage to the brittle material, it is important that the wafers — just 120 µm thin — are blown evenly on both sides. Hot air is then blown into the tunnel itself. As a result, the remaining thin film of water fully evaporates. A continuous exchange of air in the tunnel is indispensable for a rapid drying process. As the air temperature is of crucial importance for a reproducible drying process, it is recorded in the tunnel via a thermal probe. A PID microcontroller is used to continuously adjust the heating power of the air heater. Broad spectrum of power Leister’s line of LHS air heaters is ideally suited for such demanding tasks. Heating powers from 550 Watt to 32 Kilowatt are covered with the various models offered within the LHS line (Leister Heat Sources). The LHS line is available in all power classes in the CLASSIC, PREMIUM and SYSTEM models. These heaters are primarily distinguished by their control capability. When it comes to the high requirements for thermal stability, as demanded by Tronrud for the PV industry, the LHS SYSTEM air heater is the ideal choice. This device can be controlled via a remote-controlled interface using an external PLC. That means the air heater can easily be integrated into a controlled loop system. An air temperature of 100 C (212 F) with a corresponding flow rate is required in the tunnel for the described Tronrud drying module. A Leister LHS SYSTEM 60S air heater with a heating capacity of six Kilowatts has therefore been used to accomplish this. As a result, the system achieves a maximum feed of 14 meters per minute (~46 feet per minute), equating to more than 3000 wafers an hour, or a cycle time of slightly more than one second per wafer. Availability ensured Broad power spectrum and ease of control demonstrated by the LHS air heaters were not the only advantages that impressed the engineers at Tronrud. The positive experiences reported by system manufacturers throughout when using Leister devices in the past few years was ample proof of the high standard of quality distinguishing the products of the long-established Swiss company. Leister has a close-knit network of sales and service points. The international service is essential for the Norwegians. Thanks to this service, Leister is able to ensure the high availability of their systems and production lines at all times. Even more efficient Besides air heaters, blowers and hot air blowers, Leister has recently added air radiation heaters to its product portfolio. Air radiation heaters can be operated autonomously as infrared radiators, but have been specially designed for the combination of radiation with hot air. This combination enables an even more efficient and gentler drying process. The radiator heats the material evenly so that the liquid film evaporates. The hot air flow assists the evaporation and conveys the moisture out of the processing room with the air flow. The first trials for drying PV wafers have yielded very positive results. A promising future Photovoltaics belongs to the future, no question. – Above all, if it succeeds in keeping the production costs as low as possible through high unit volumes and short cycle times. And also if the quality and reliability can continue to be guaranteed at the same time. With its air heaters and air radiation heaters, Leister supports this prospect of a prosperous future awaiting the photovoltaic industry. Customer: Tronrud Engineering SA, Norway, www.tronrud.no Supplier of air heaters: Leister Process Technologies, Switzerland, www.leister.com Sales and Service Partner: Inter-Supply, Norway, www.inter-supply.no Author: Oliver Hinz, Business Development Manager, Leister Photos: Tronrud / Leister Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: