|

Leister's product line of air heaters and heater/blower combination tools are available in a range of kilowatts, voltages, sizes, etc. They also offer many of their heaters with a selection of control options: basic heaters with no control electronics (on/off) 'CLASSIC', heaters with power electronics that allow open-loop control of percentage power output via an onboard potentiometer 'PREMIUM', and heaters with full onboard temperature controllers combined with a thermocouple feedback loop (closed-loop control) 'SYSTEM'. This application note is focused on the functionality of the Leister SYSTEM tools, which are the more sophisticated, closed-loop control tools. Leister SYSTEM Heaters Leister SYSTEM heaters come with a built in thermocouple, an on-board temperature controller, and a digital display. This gives the user flexibility in how the heater is controlled. Before describing the various modes in which the SYSTEM heater can be used we should first understand some of the terminology:

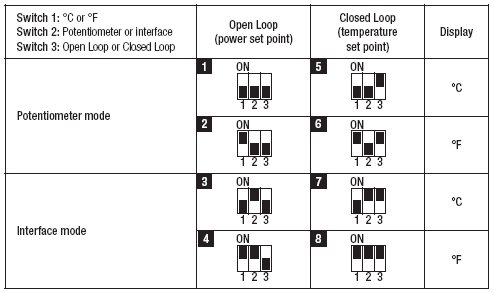

The Leister SYSTEM heaters can be configured for use in five different control modes. Depending on the tool, the desired mode is selected through a digital settings menu or by setting internal dipswitches. The dipswitch settings for a SYSTEM heater are given in Table 1. The dipswitches (or menu selections) determine two important things – whether the tool's internal closed-loop is activated or deactivated and whether the tool is using the on-unit potentiometer or an external control interface to provide the set point. The available modes of operation are outlined below:

If after reading this Application Note on the Leister SYSTEM heaters you still have questions regarding their use and set up please contact your technical representative.

Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: