|

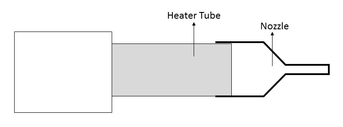

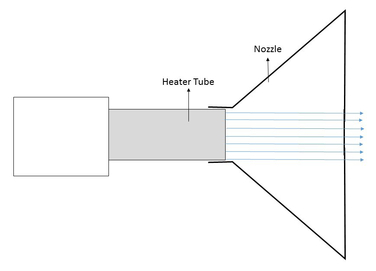

Air heaters are used for many applications and the nozzle that should be attached to the outlet of your heater depends on the requirements of your application. In designing a hot air process, careful thought is usually given to the type of heater, size of heater, etc. but nozzle selection is often done as an afterthought without much consideration. Many people underestimate the importance of good nozzle design to the success of their process heat application. 1. What is the purpose of the nozzle? The first question to ask when selecting or designing a nozzle is ‘what do you want to accomplish?’ Do you want to focus the air into a fast moving stream? Or do you want to spread the air out and create a diffuse but slower moving blanket of hot air? Defining the purpose of the nozzle will help you narrow down the overall shape and type, before moving onto more specific aspects such as the required dimensions. 2. What is the minimum nozzle outlet size that can be used with your air heater? A frequent error when choosing or designing a nozzle is to make the outlet of the nozzle too small/constrictive, usually when trying to focus the air to a small point. However, by constricting the air flow too much you may be causing heat to back up into the heater electronics causing damage. Alternatively, if the heater is fitted with overheat protection, it may continually shut itself off. A scenario such as the one in Figure 4 should be avoided. If you cannot make the nozzle outlet larger without compromising your results consider changing to a smaller and less powerful heater with a smaller outlet. 3. What is the maximum nozzle outlet size that can be used with your air heater? Using a nozzle that is too big will not damage your heater but it will be ineffective due to a lack of back pressure. The air exiting the heater wants to travel in a straight line. In order for this air to fill the entire outlet of the nozzle there needs to be a small amount of pressure forcing the hot air to fill the space and exit the nozzle somewhat homogeneously. Choose a nozzle that does not create too much back pressure as this will have a similar effect as a nozzle that is too small. Below is an example of what happens when a nozzle is too big, air exits the nozzle in a straight line rather than filling the entire outlet. Remember that air will take the path of least resistance. You have to force it to move away from its linear trajectory. This can be accomplished in a very simple way such as altering the hole-pattern on the nozzle outlet or it may require a complex solution such as a special baffle inside the nozzle.

Nozzle selection is not always straightforward and there are applications that require complex nozzle design. For help with nozzle selection, contact STANMECH. Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: