|

In rural Vietnam and many other areas of Asia, people still cook with fossil fuels, such as bottled gas. Read this article to find out how Leister is supporting an international research team in its search for a more environmentally friendly alternative.

Watertight welding of plastic membranes is one of many Leister competencies in underground engineering. In the late summer of 2021, VARIMAT and Co in Bern began the renovation of the Weyermannshaus open air swimming pool. Swimmers are set to return to their “Weyerli” from May 14, 2022.

Clean drinking water is a precious commodity. The central Swiss company Alois Bader AG used Leister extruders to produce a recently installed reservoir for supplying drinking water to the community of Giswil in the canton of Obwalden.

Whether large, small, with sugar, milk or foamed milk, black and strong, traditionally at home, at work, on the go or consumed in a café. Coffee is the second most common consumed drink after water worldwide. Read this blog post to find out what connects PROBAT, Leister and coffee.

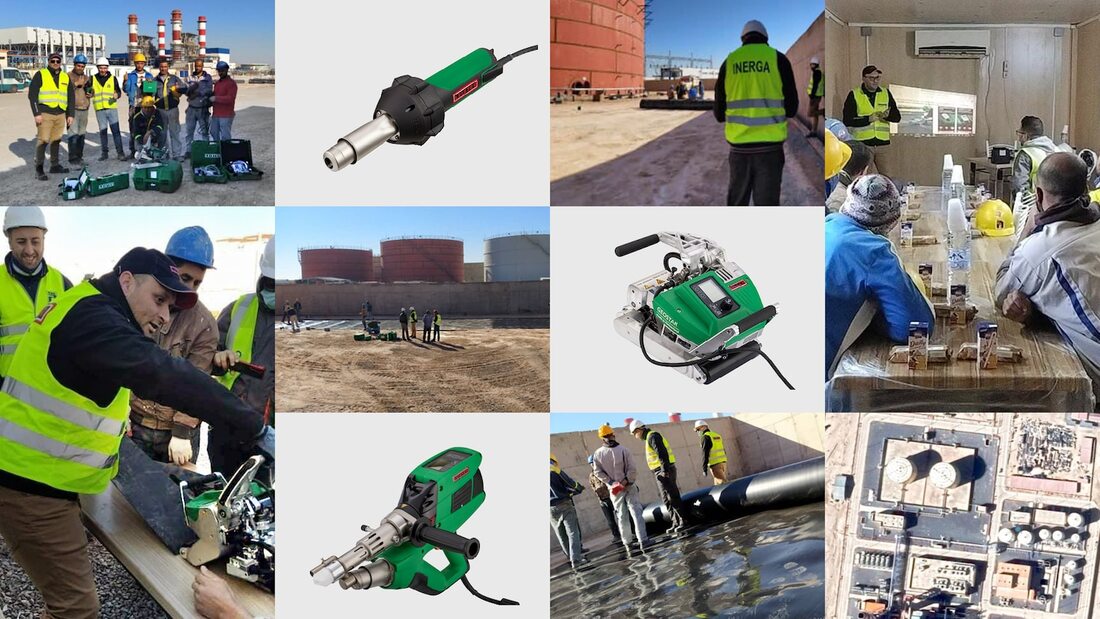

In Egypt, the largest wastewater treatment plant in Africa, Bahr Al-Baqar, is being built. Due to drought and rapid population growth, there is an urgent need to treat agricultural wastewater and recycle the clean water obtained. In this article, you will learn what equipment from Leister was used in this civil engineering project.

The Algerian company Inerga is now independently completing large geo projects thanks to the excellent cooperation with Leister's Algerian distributor, ChimiBat. Read more in this blog post.

Development, production and worldwide distribution of machines and equipment used to install elastic floor coverings are some of Leister's core competencies. The battery-powered GROOVER 500-LP joint milling machine and the UNIFLOOR E and UNIFLOOR 500 automatic floor welding machines have inspired Swiss, floor installers Werner, Mischa and Sascha Morf. At the time of this interview, they were working on school building renovations in Zurich. You can read more about them in this blog post, as we were allowed to look over their shoulder at work.

FS DECO is an Algerian company that specializes in installing resilient and hard floor coverings. The team of qualified floor installers advise the Algerian clientele professionally and individually in the selection of indoor and outdoor floor coverings. Whether carpet, parquet, laminate or elastic coverings made of PVC (vinyl) and linoleum for a wide variety of applications such as operating theatres, school classrooms, offices and much more.

The successful Leister distributor, RIKAZ, sells Leister equipment for plastic welding in Kazakhstan. In this blog post, we discuss how Leister’s automatic welding machines are used to weld the geomembranes on large gold mine, tailings ponds. Tight weld seams are also crucial here to ensure that no contaminated water enters into the soil or groundwater.

The AZART Group of companies has its headquarters in St. Petersburg in Russia and has been manufacturing inflatable products made of PVC fabrics for state authorities and the entertainment industry for over ten years. In recent years, AZART has continuously expanded its product range and is now successfully represented on the market in various sectors.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: