|

The two hold-down assemblies and the green belt in the picture below keep the top layer of membrane flat on the bottom layer as it is heated by the nozzle, just before the drive tire presses down on it.

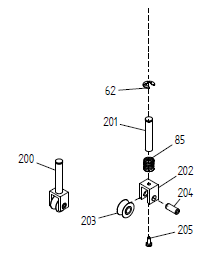

Each hold-down assembly contains the following parts:

Periodically check on each assembly that the U-profile (202) is tight to the guide pillar (201). Sometimes the screw (205) works itself loose. If this is not corrected, the screw may loosen entirely, and it and the U-profile (202), roll pin (204), roller (203) and spring (85) will fall off.

Fixing a Loose Hold-Down Assembly

Replacing a Lost Hold-Down Assembly

Assembling a Hold-Down Assembly from Parts

Still having problems? We offer repair services by factory trained technicians. Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: