|

Many of Leister’s tools utilize a lock pin to hold the nozzle in position during welding and cooldown. The lock pin is designed to snap if excessive force is put on the heater in order to prevent more expensive damage to the tool.

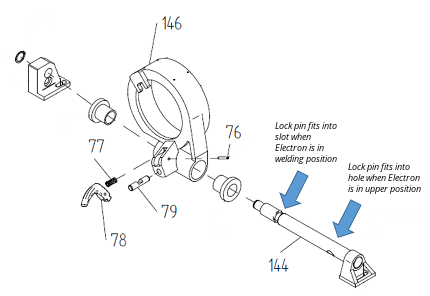

The most common reason for a lock pin to bend or break is the tool being lifted or carried incorrectly. The correct methods of carrying the tool are with both hands under the frame, or with one hand under the frame and the other holding the black carrying handle. In this guide, parts will be referred to using the numbers indicated in the VARIMAT V drawing below. As an example, see lock pin (79). Tools needed:

Tools which may be needed:

Method:

Bonus: How the Lock Pin Works

The heater with nozzle fits into the tool holder (146). To move the nozzle from the upper position to the weld position, squeeze the trigger (78) which swivels on roll pin (76), pulls on the lock pin (79) and pushes on the spring (77). Then drop the nozzle down, tuck it under the drive tire and release the trigger. The spring pushes the trigger down and the trigger pushes the lock pin forward into the slot in the guide shaft (144).

Comments are closed.

|

|

STANMECH Technologies Inc.

944 Zelco Drive Burlington ON L7L 4Y3 | 1-888-438-6324 | [email protected] Terms of Use Privacy Terms and Conditions of Sale Warranty Policies |

|

Proud Member of: