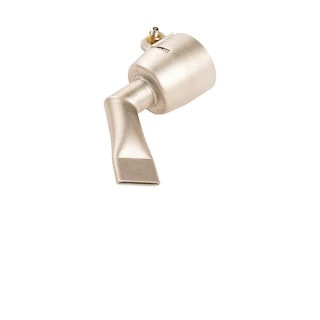

TRIAC AT Hot Air Hand Tool

|

|

|

|

|

The TRIAC AT offers the advantages of closed-loop temperature control, independent air flow control, and a digital display. Leister’s unique »e-Drive« control system makes it easy to use and includes a lock feature to prevent accidental setting changes while the tool is in use. Since mid-2020, the TRIAC AT now has an optional ECO mode which reduces air flow when the tool is idle, automatically returning the tool to the user's settings once it is picked up again. ECO mode offers 40% energy savings and a 50% reduction in noise while extending the life of the tool.

- Digital display shows precise value of temperature and level of air flow selected; warnings such as undervoltage, replace carbon brushes soon, and tool overheated included on display

- Cool down mode with automatic shut-off

- Independent temperature and air flow control

- Automatic and constant temperature adjustment independent of voltage fluctuations and environmental conditions

- Easy and comfortable to use

- Automatic shut-off when carbon brushes are worn to prevent expensive damages

- Additional heater tube sleeve helps prevent burns during use

- Electronic protection of heating element

- Construction site tested and suitable for outdoor use

Why Buy From Us

The TRIAC AT is available in Canada only through STANMECH and our distributor network. Tools bought through us are electrically certified for use in Canada. In many cases this entails replacing cords or switches in the tool to meet stringent CSA standards. Each tool is physically inspected by an approved field inspector prior to certification. We offer same-day shipping on in-stock items from our facility in Burlington, Ontario, Canada.

Technical Data

Voltage |

V |

120 |

230 |

Frequency |

Hz |

50 / 60 |

50 / 60 |

Power Consumption |

kW |

1.6 |

1.6 |

Temperature |

°C |

40 - 650 |

40 - 650 |

Air flow |

l/min |

120 - 240 |

120 - 240 |

Noise level |

dB |

67 |

67 |

Size (L x W) |

mm |

335 x 90, handle Ø 56 |

335 x 90, handle Ø 56 |

Weight |

kg |

1.0 |

1.0 |

Approval markings |

|

CE, C-UL-US |

CE, QPS |

Electrical protection |

|

Class II |

Class II |

Part Numbers

141.382: TRIAC AT - 120 V / 1600 W

141.314: TRIAC AT - 230 V / 1600 W

141.314: TRIAC AT - 230 V / 1600 W

Accessories

* Suitable for speed welding nozzle

* Suitable tubular nozzle required

* Suitable tubular nozzle required